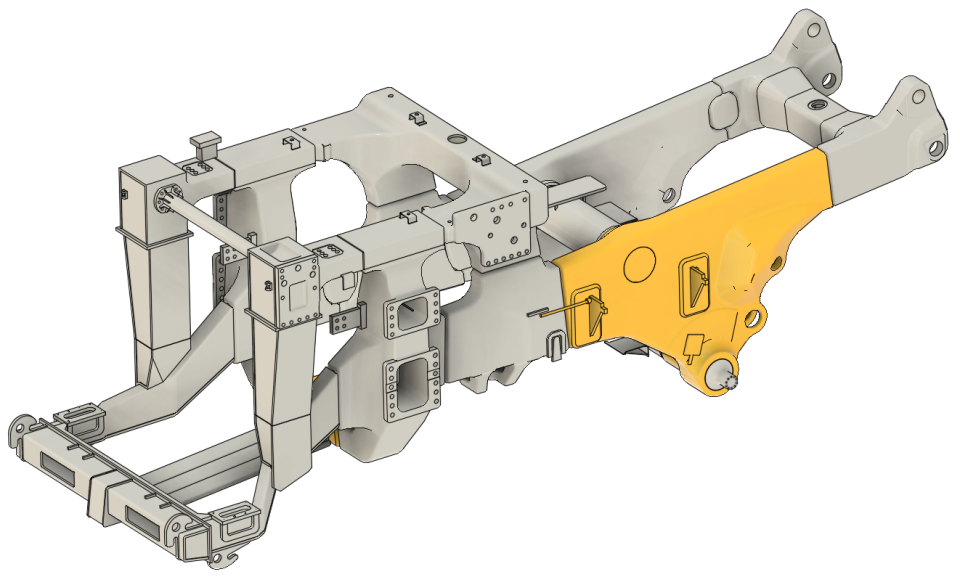

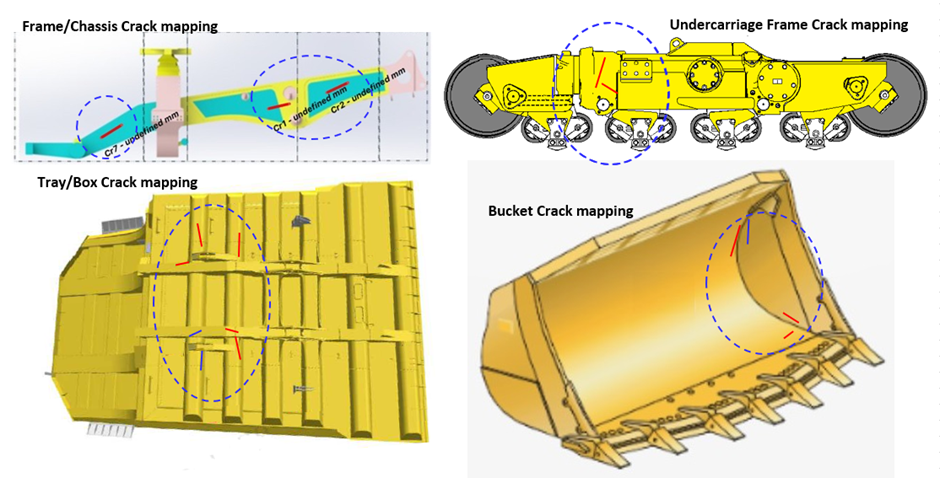

Crack Mapping of Off-Highway Trucks chassis & Shovel Components

Large mobile equipment structures experience extreme stresses that cause metal fatigue and cracking. Maintenance teams measure, monitor, analyze, and repair these cracks to prevent escalation and structural failure. Key Capabilities Immediate Benefits

Crack Mapping of Off-Highway Trucks chassis & Shovel Components Read More »