Digitized Field Inspection Tools to assist Reliability Planning

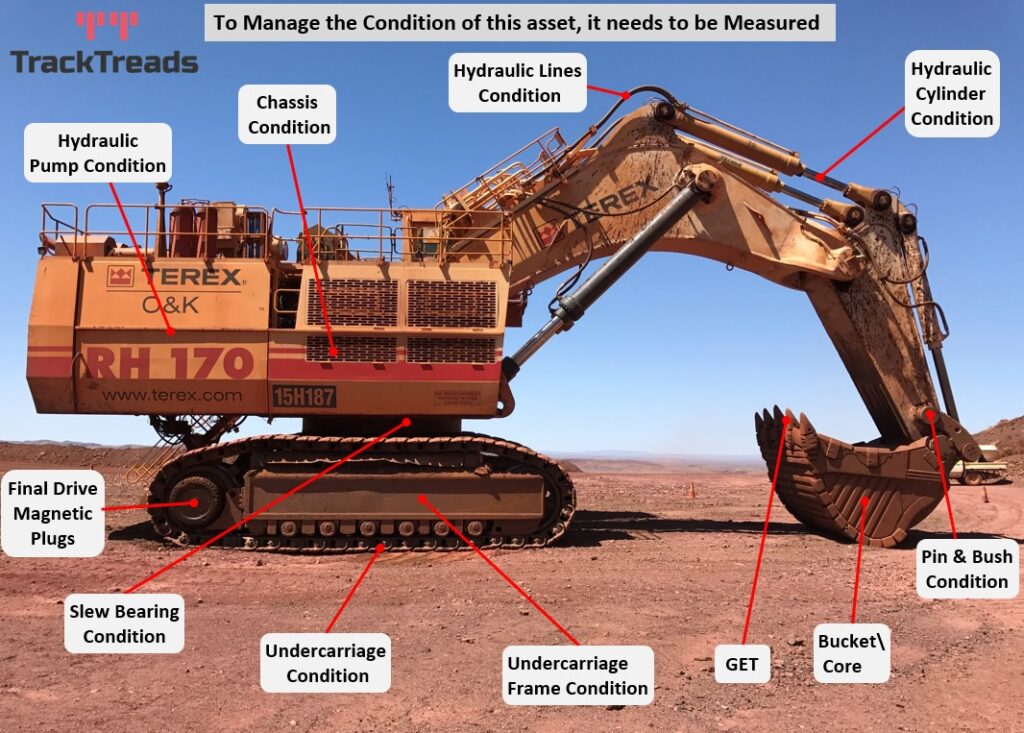

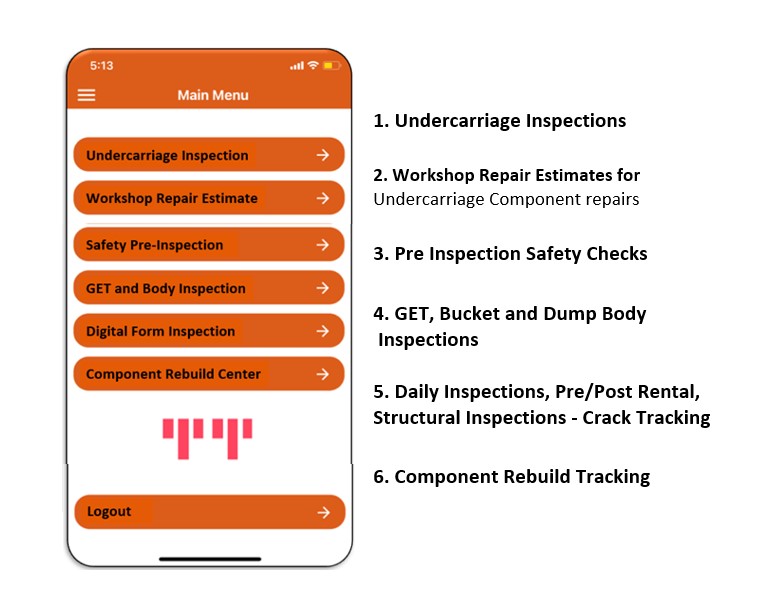

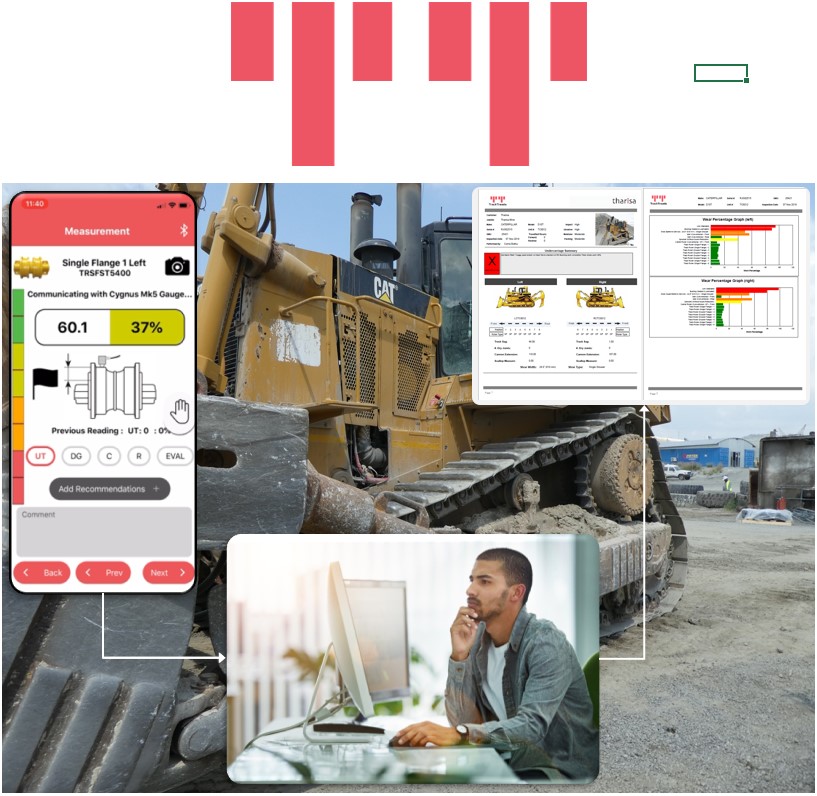

The task of Reliability Engineers and planners for the mine-site is to plan and schedule maintenance and repairs to the mobile equipment in order for the equipment to achieve as much uptime as possible for the least amount of cost. This is an extremely complex task requiring the planners to balance many competing variables such […]

Digitized Field Inspection Tools to assist Reliability Planning Read More »