Dump Bodies

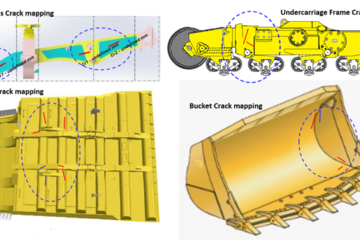

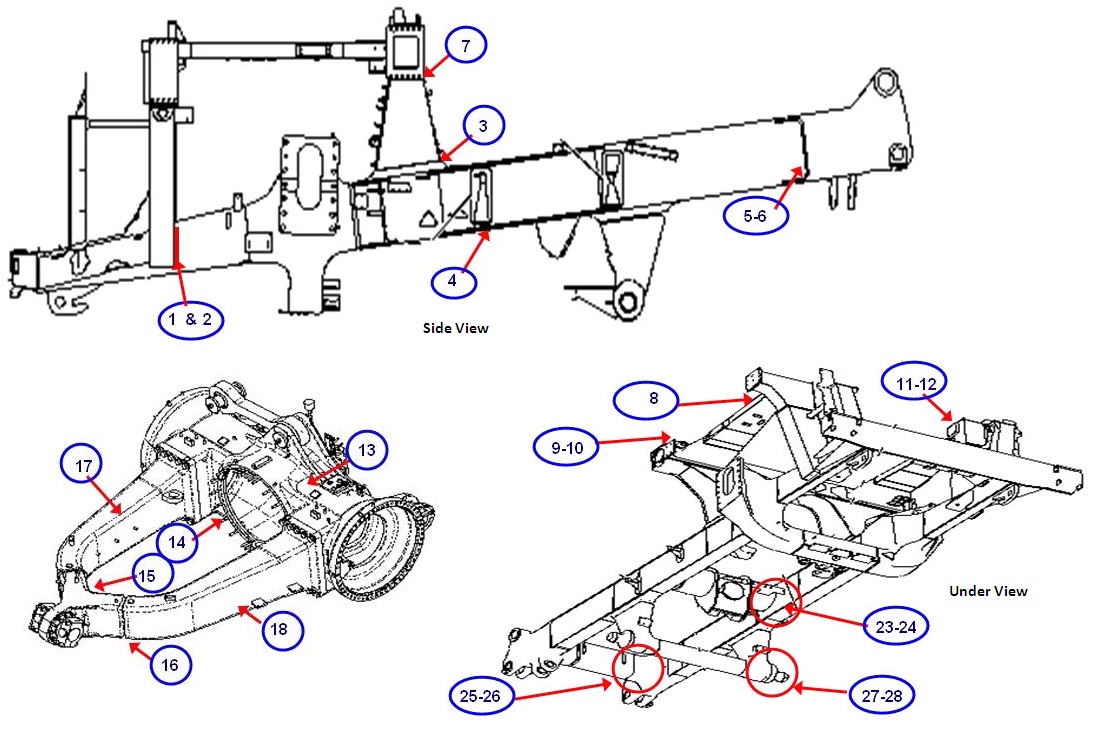

Crack Management on Field Equipment

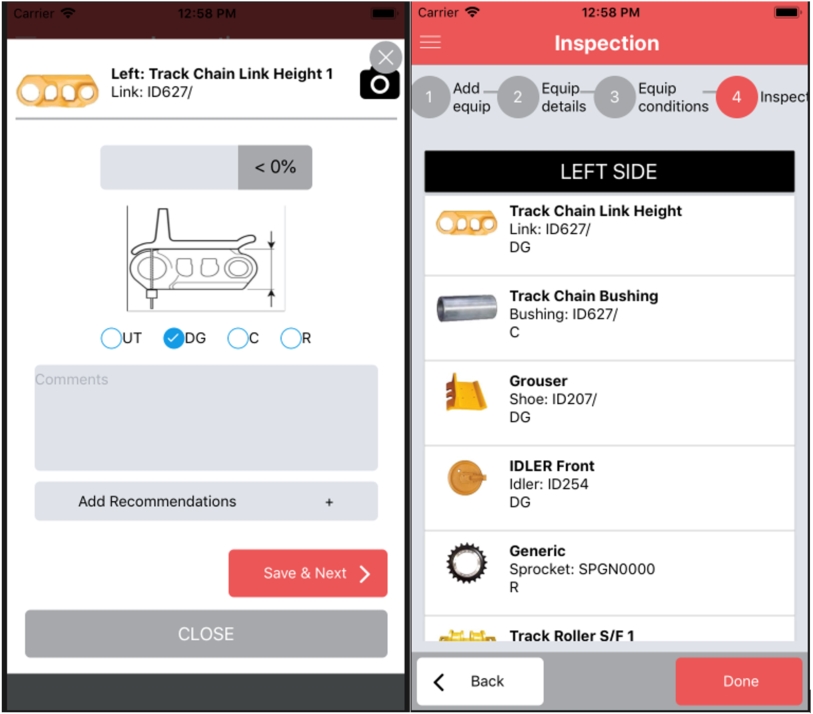

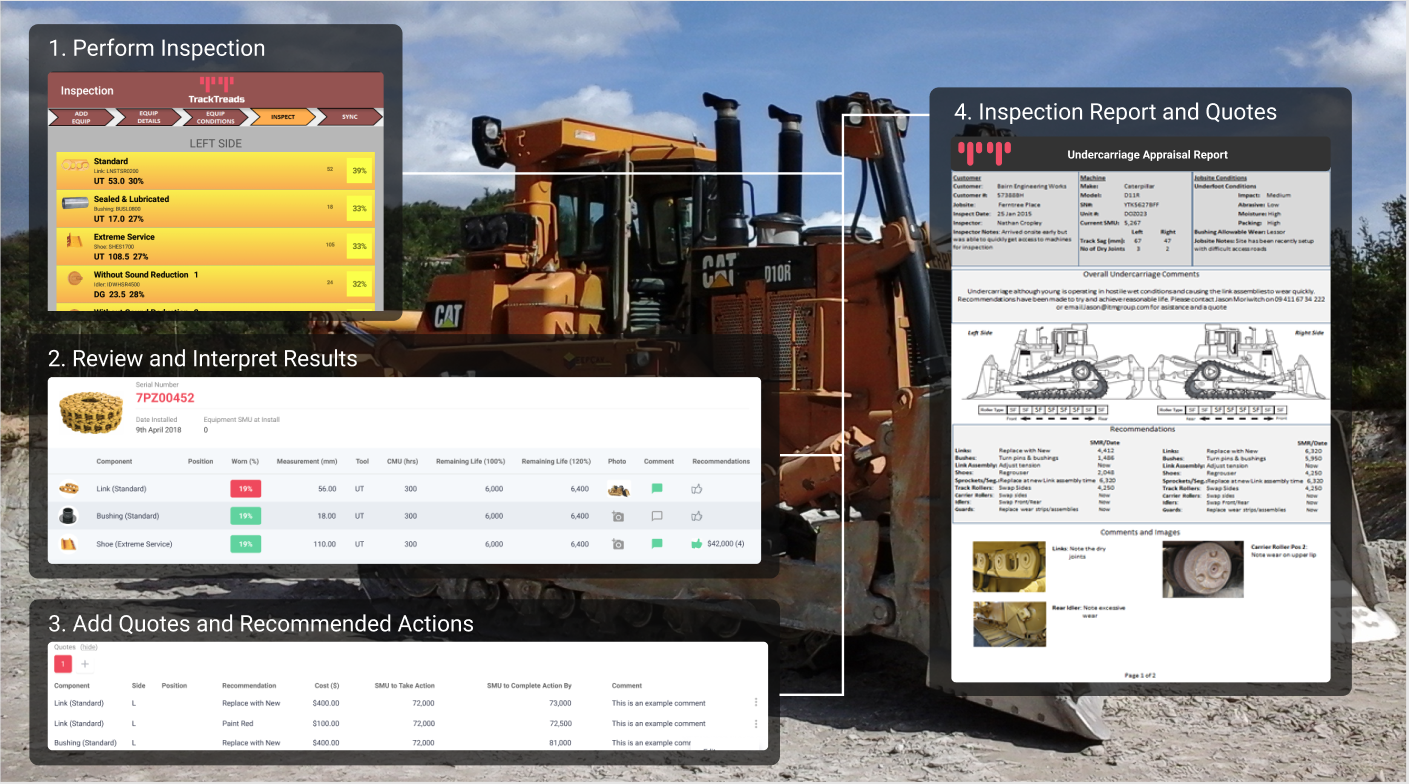

The TrackTreads system provides “cradle to grave” Crack Management in Mobile Fleet Structures. There are 4 main steps covered in the management of these cracks Identification, measurement and setting of limits Field Inspectors capture, using mobile phones or tablets, the precise position of the crack on the structure by drawing Read more…