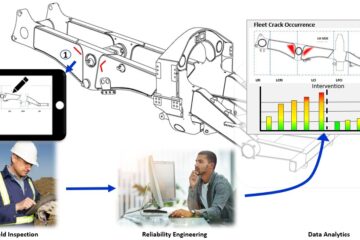

Field Inspections

Inspecting and recording cracking on Mobile Field Equipment using a mobile

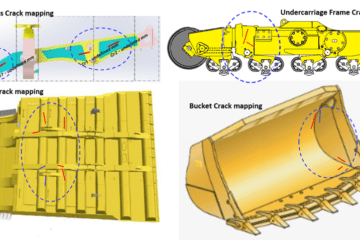

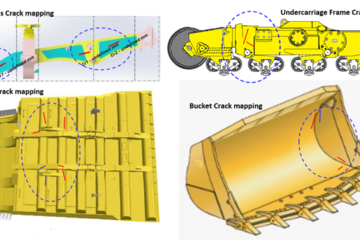

Cracks occur any many field equipment components. Management of these cracks ensures that catastrophic failure is avoided. Capturing crack data electronically provides some immediate benefits. There are 4 main steps covered for digitizing crack management. Field Inspectors capture, using mobile phones or tablets, the precise position of the crack on Read more…