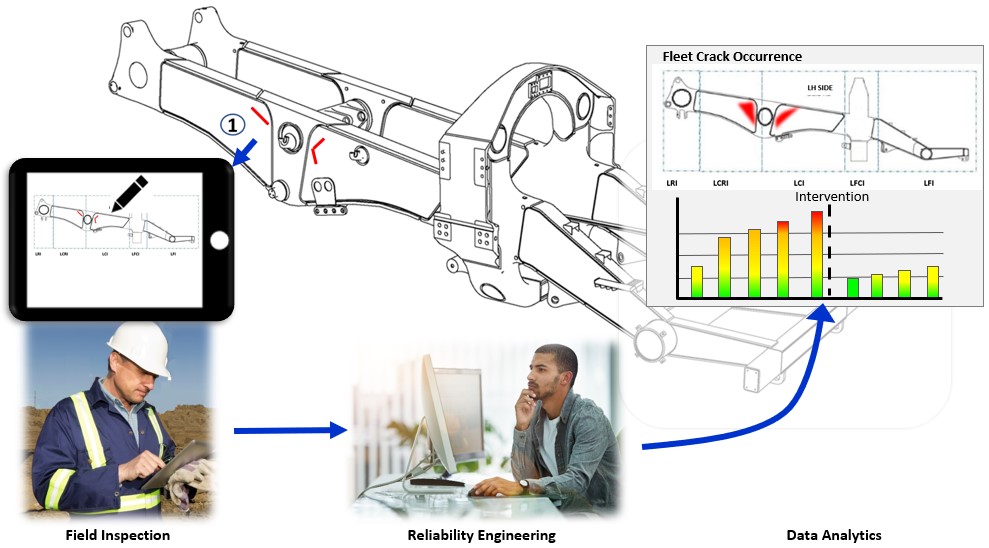

Digitizing structural field inspections on mobile equipment such as trucks, shovels and dozers allows the collection and recording of the length and position of cracks on components common to the fleet of machines.

Crack Length Measurement – Each following inspection will display the existing cracks allowing a further measurement to be recorded. The rate of growth is calculated and tracked for each inspection

Status of crack – Cracks can be marked as fixed

Re-cracking – re-cracking can be identified where pre-existing cracks were previously recorded

Cracks linked to Components – Cracks are connected to a component such as a chassis on each machine allowing the frequency, length, and propagation rate of the cracks to be tracked across a fleet of machines.

Crack Status – the status of all un-repaired cracks can be tracked across the entire fleet. This is useful data when planning work required

Work Orders – Crack images, length and the exact location can be transferred directly into the work order for the service technician or welder to have the exact information available when completing the repair

0 Comments