Sometimes is it good to go back to basics. 4 Basic Pillars of Undercarriage Management

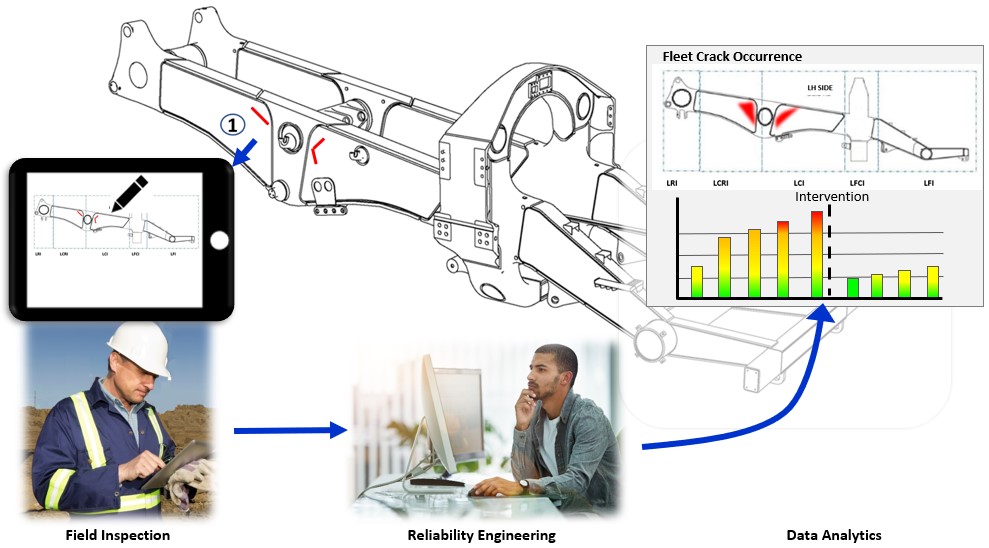

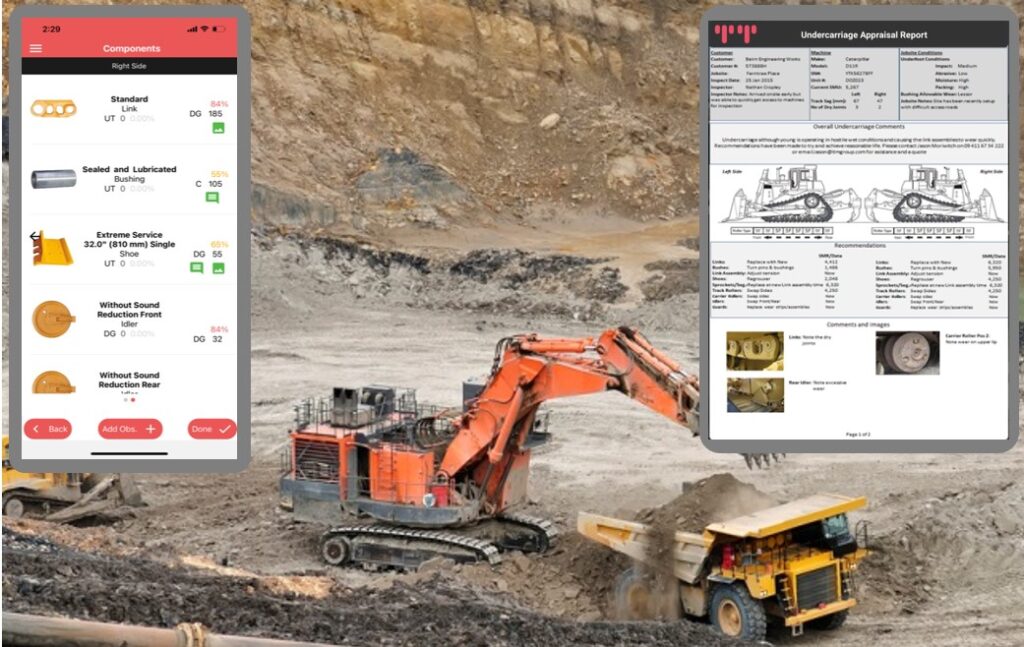

Collecting Undercarriage Field Inspection data – Measuring the undercarriage component wear needs to be done regularly and accurately. Readings should then be supported by images and comments. Automatic calculation of % wear and the physical limits along with any prior reading history help the Inspector provide quality information. All this functionality should be available offline […]

Sometimes is it good to go back to basics. 4 Basic Pillars of Undercarriage Management Read More »