Data

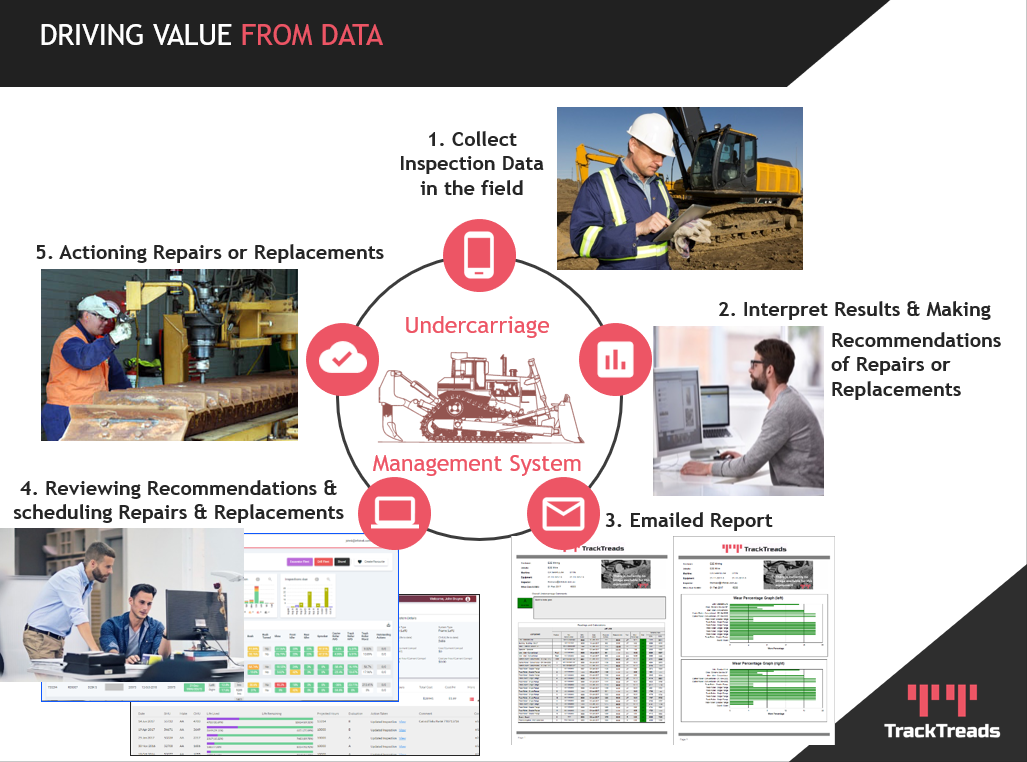

Driving Value from the Deluge of Data

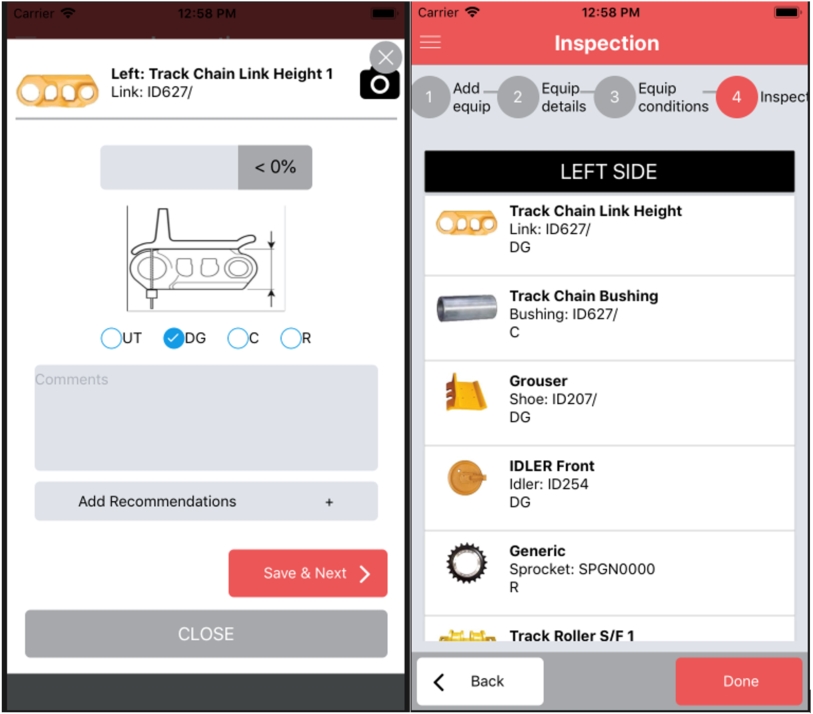

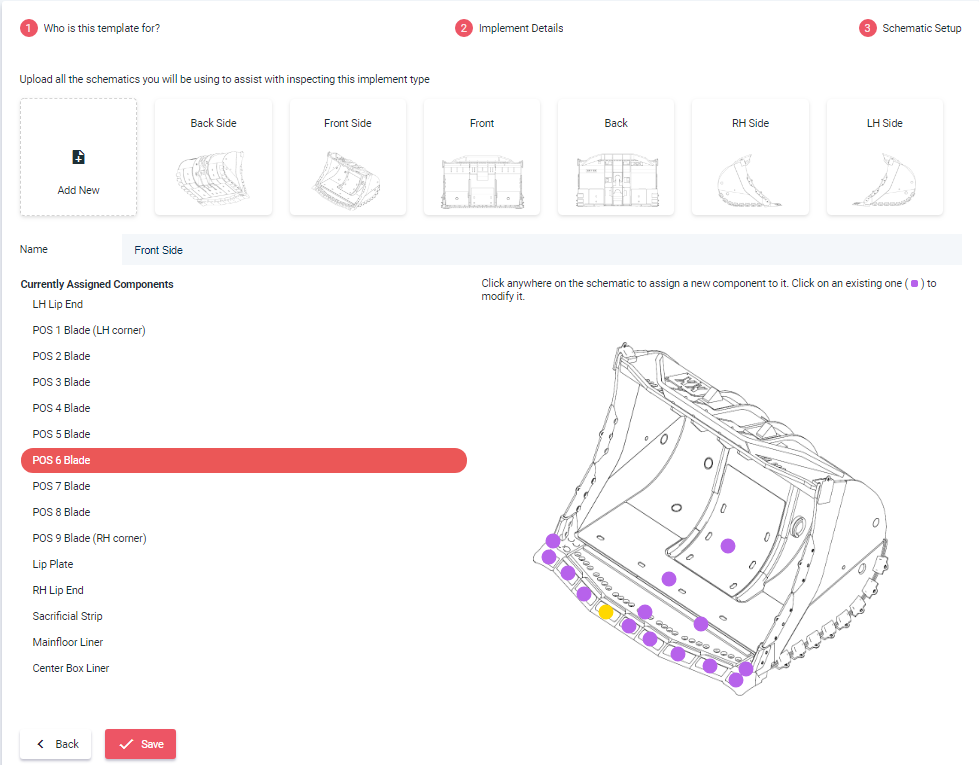

In our data rich world businesses are generally more efficient at collecting data than they are at using it. Efficiently using the data collected, to drive value-based decisions, can be what takes your business, or more importantly your profit margin, to the next level. TrackTreads is about providing software to support not only your collection of data, but also enhancing your ability to analyse and utilize your data with ease. TrackTreads provides tools that assist Read more…