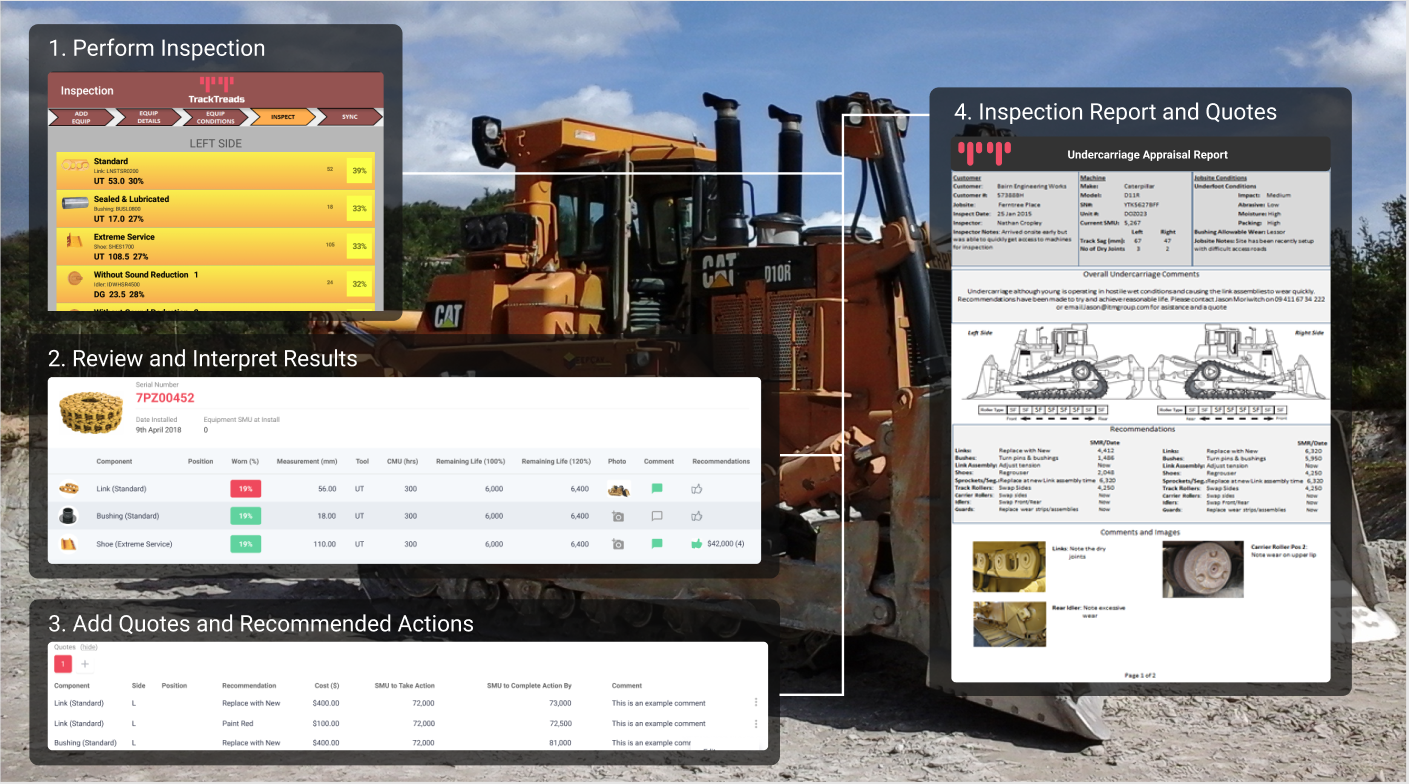

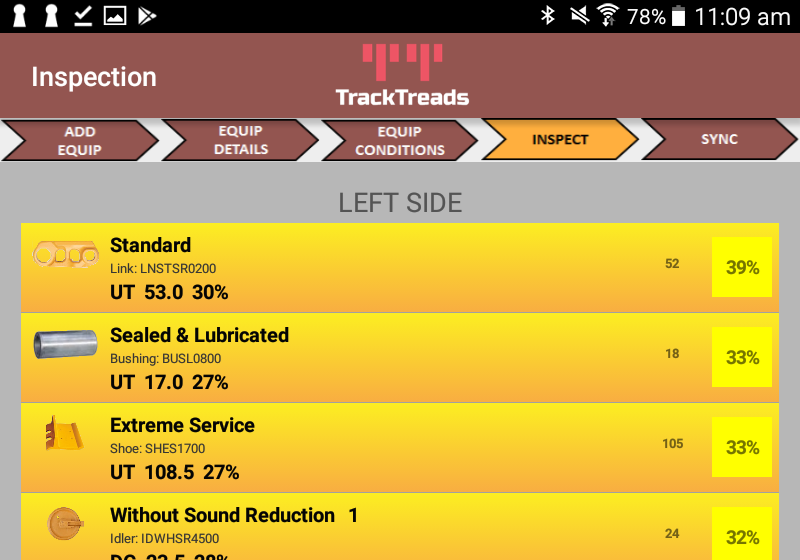

Mobile App

Track Inspection Data Rapidly Converted Into A Quote

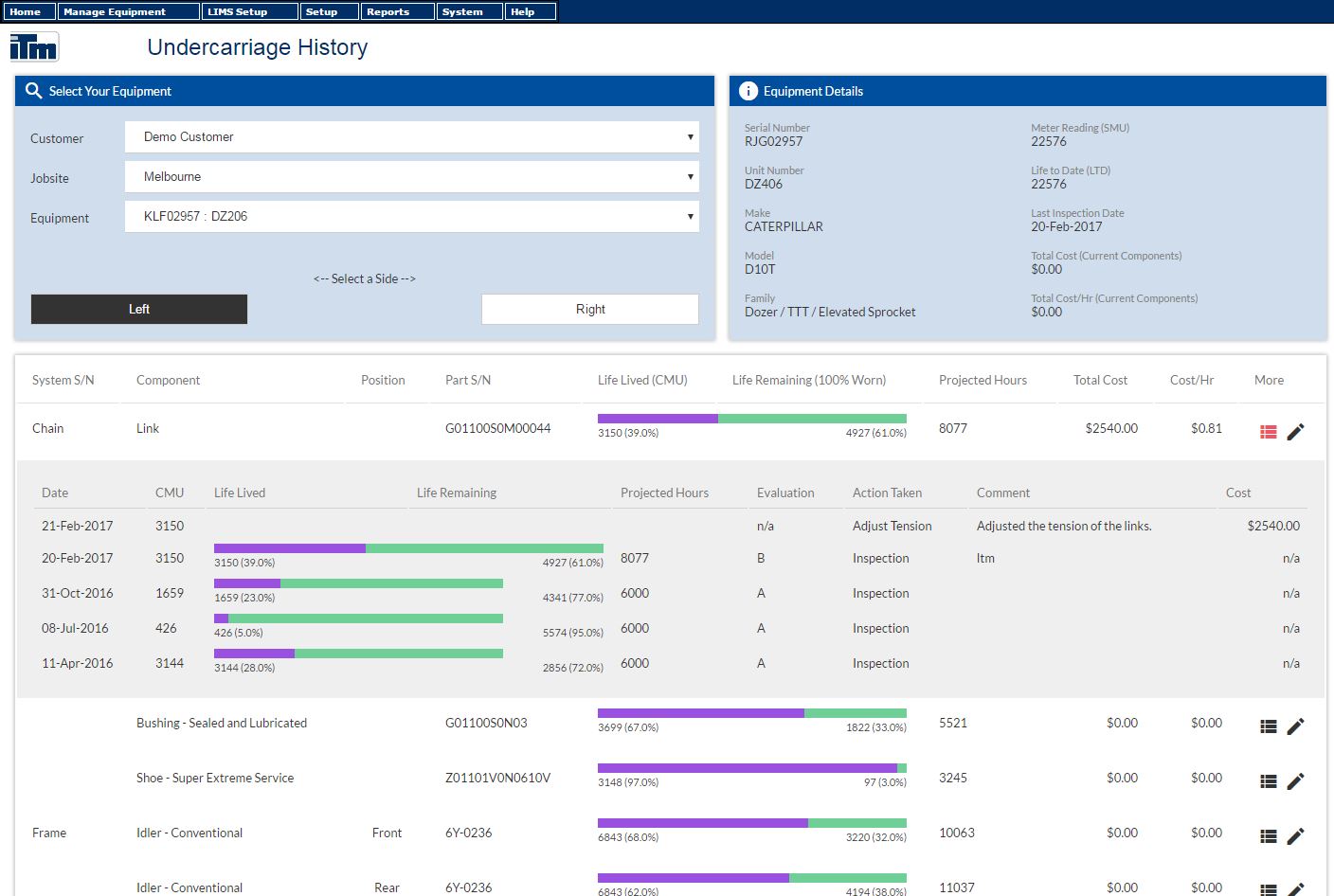

TrackTreads have recently updated the Undercarriage Inspection Management system to enable quick generation of a quote for repairs or part replacements. Inspectors can now perform an inspection on any make or model and deliver to the customer, both the inspection report and a formal quote within minutes of completing the inspection. The shorter the turnaround time, the greater the likelihood of a successful sale. Inspectors measure the undercarriage using the mobile application connected to Read more…