News

Recent News

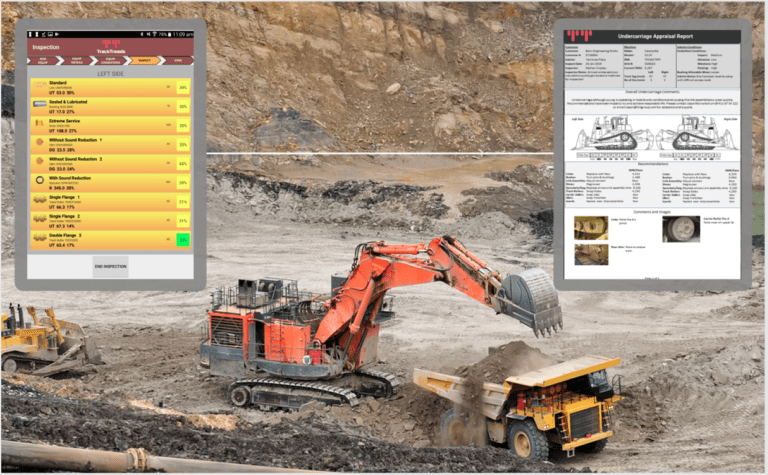

Chassis Inspections made easy.

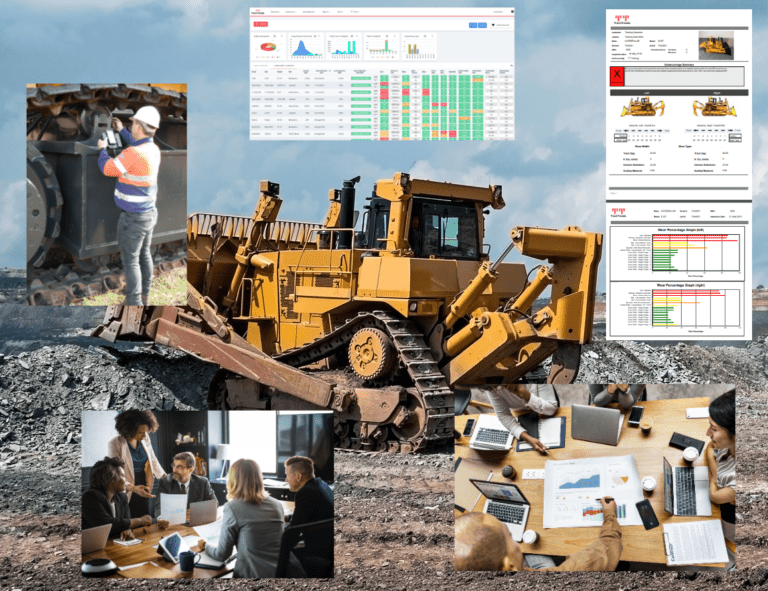

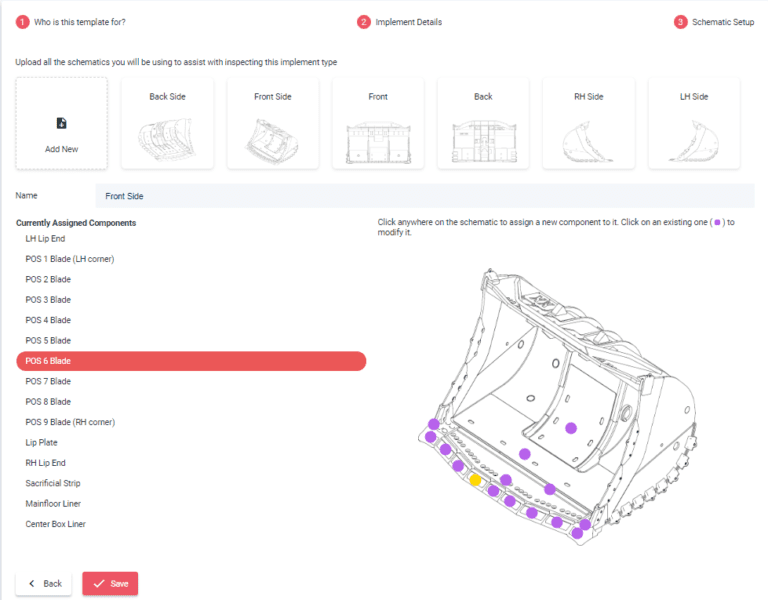

TrackTreads Get/Bucket and Wear Surface Management Inspection software can be used for inspecting and managing Heavy Earthmoving Equipment Chassis for any machine. Record using you mobile phone: To get further information and arrange a free demontration simply fill in the form below.

Doing nothing is no substitute to proper condition monitoring.

Condition monitoring is one of the pillars of equipment Maintenance. Every maintenance department ensures Oil samples are taken regularly, but that wasn’t necessarily the case 20 years ago. Imagine asking a maintenance department today if they take oil samples and being told, ‘No, we’re too busy to take Oil Samples’.

What is the cost of not Managing Undercarriage?

Undercarriage inspections collect inspection data from the field and allow the calculation of the current degree of wear on each undercarriage component and also allow a forecast of the remaining life on that component. This is just the beginning of the information that then becomes available. As with any area

Setting the Industry Standard for Undercarriage Management Software

When it comes to providing Undercarriage Management Software, customers are looking for more than just a simple condition report. They are wanting and needing additional functionality to fully manage, monitor and track the history of Undercarriage components as a minimum. On top of that, they want to be guaranteed that

What are Component Wear and Failure profiles?

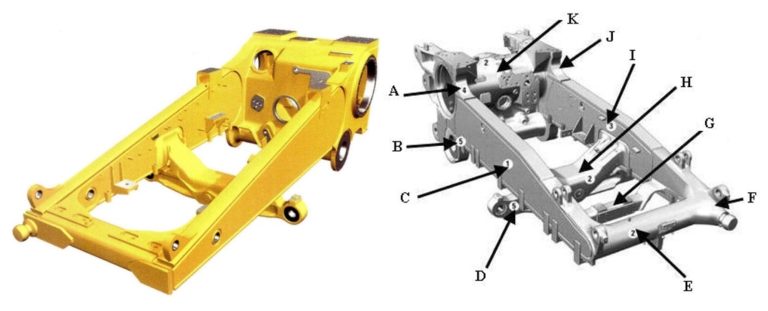

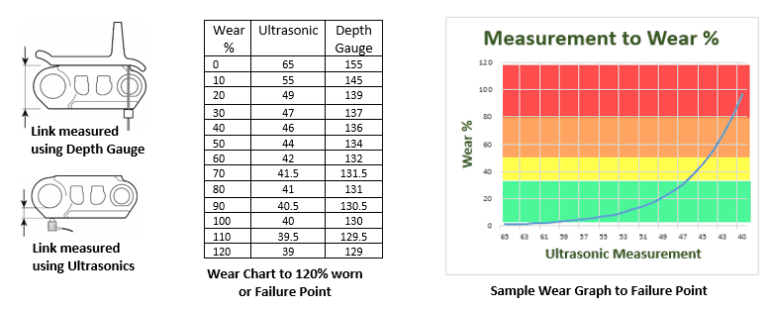

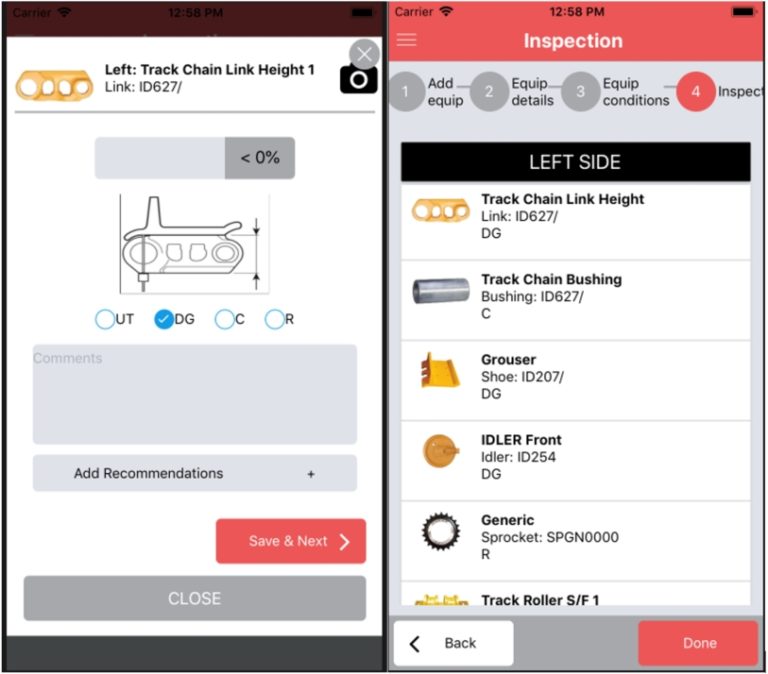

The TrackTreads Undercarriage (UC) Management Software enables UC inspectors to measure Undercarriage components in the field using the Mobile Application connected with an Ultrasonic Tool. This requires each component to be defined. The Undercarriage system is comprised of multiple different components each with their own wear profile definition. Each OEM

Why PDF condition reports are no longer enough.

The future profitability of mining or construction, as with any businesses, lies in the effective use of Business Intelligence. BI isn’t just your data, it’s the information you get from effectively analysing your data. It’s the ability to take large, and often very large datasets, and distil them down to

Analytics driving the Future of Undercarriage Management in Mining

Undercarriage Inspection data provides the basis of equipment condition monitoring and drives the decisions to repair and/or replace components. These are the day to day tasks handled by the TrackTreads system, but there is so much more. The lost value associated with the old chain is the 10% of wear

Correct undercarriage component replacement stategies save money

There is a bucket load of money to be saved from Undercarriage Components that are changed out too early.Many operators of heavy tracked machinery are hard pressed for time in their daily routines to consider the cost and lost savings from components being removed prior to reaching 100% worn. Understanding

Using Technology to lever improved Undercarriage Management

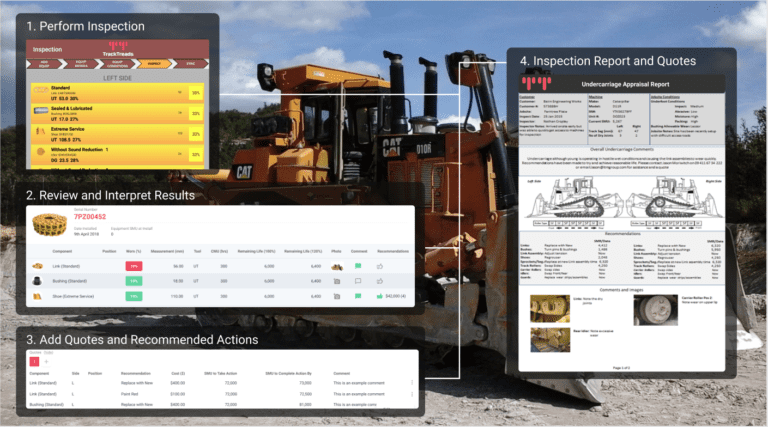

Technology is everywhere today and is being used to increase efficiency and reduce costs. Undercarriage and Wear Surface management are a perfect example. In the past, components were inspected manually, with readings jotted on paper before being transferred to some system, generally a spreadsheet. The measurements were then compared with

An end to end solution for managing Undercarriage and Wear Surfaces

TrackTreads has developed a solution that enables customers to collect and manage their own Undercarriage and Wear Surface inspection data. The system then provides wear forecasting calculated from the inspection data as well as other usage metrics and reports including cost analysis. Customers wanting to manage and control their

Reactive to Proactive Undercarriage Management

Improving your level of Undercarriage sophistication is an essential first step towards a comprehensive Undercarriage strategy that both saves you money by reducing waste and downtime, and makes you money by increasing asset utilization and productivity. At TrackTreads we see this Undercarriage sophistication being achieved through 3 distinct stages; Understanding

Undercarriage Training Workshops – a forum for increasing knowledge and know how

All subjects are a mystery until studied in more detail. The more the subject is studied, discussed and experienced, the greater the number of subject matter experts. On a typical mine site, you will find many different subject matter experts, Tire experts, Planning experts, Drilling and Blasting experts, Operations experts

Why you need to employ an undercarriage condition management specialist.

Undercarriage can make up more than 50% of the maintenance costs of a tracked machine. Looking at the numbers, if a company is operating a fleet of tracked machines with a mix of dozers, excavators and shovels, then maintenance costs on this fleet will be substantial. Many companies operating a

Is Undercarriage Management Software actually expensive?

Software is just another tool you need in your toolkit in order to manage and repair your undercarriage components. It is no different to sending your car to the dealer for a service, and the service technician plugs his highly specialised software diagnostic tool into your car to determine the

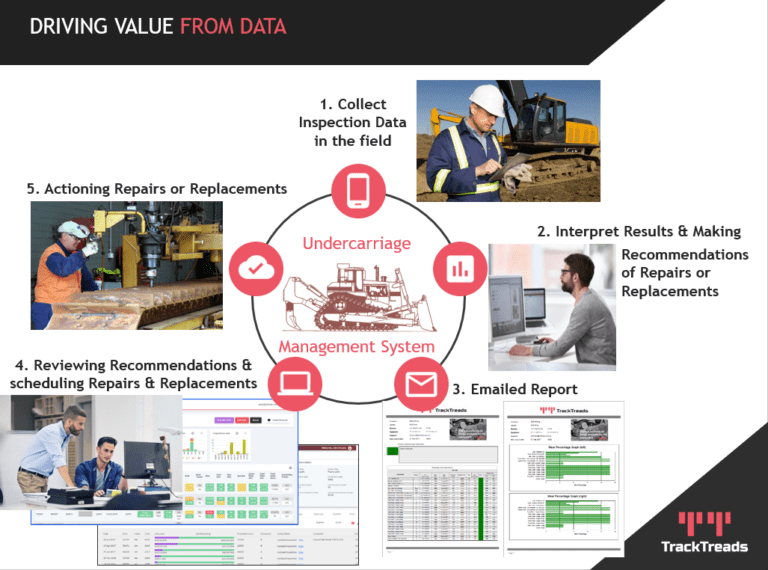

Driving Value from the Deluge of Data

In our data rich world businesses are generally more efficient at collecting data than they are at using it. Efficiently using the data collected, to drive value-based decisions, can be what takes your business, or more importantly your profit margin, to the next level. TrackTreads is about providing software to

The Customer Focussed Approach

In our modern world, there is always a heavy focus on technology. What can the software do? What bells and whistles does it have? What wonderful new technology is the software based on? These are all important details, but they often eclipse and are focussed on at the expense of

TrackTreads releases IOS mobile app to operate on iPhone or iPad

TrackTreads is very excited to announce the launch of the IOS version of our Undercarriage Inspection mobile application. The IOS version of the application comes in response to customer requests and we are pleased to be able to offer the ability to capture Undercarriage Inspections on both Android and Apple

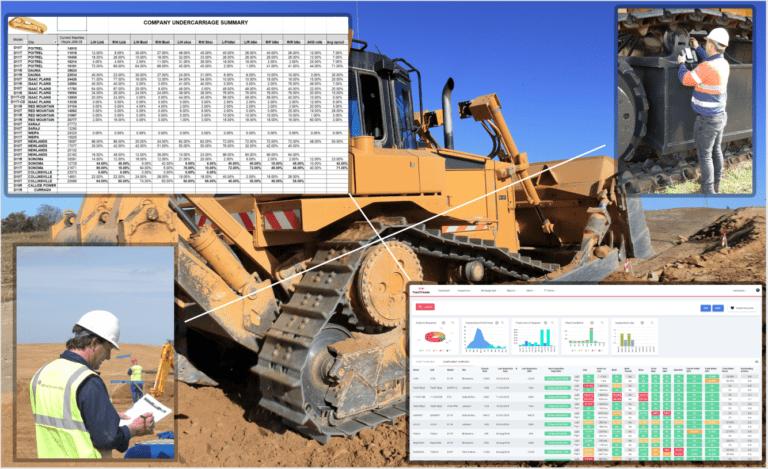

Managing Undercarriage Across Your Fleet

The TrackTreads Undercarriage Management system allows users to measure, inspect and manage their entire fleet in one system by:- Covering machines from the smallest to the largest Covering all families of tracked machines – even fixed plant Covering all brands of undercarriage manufacturers One System does it All!

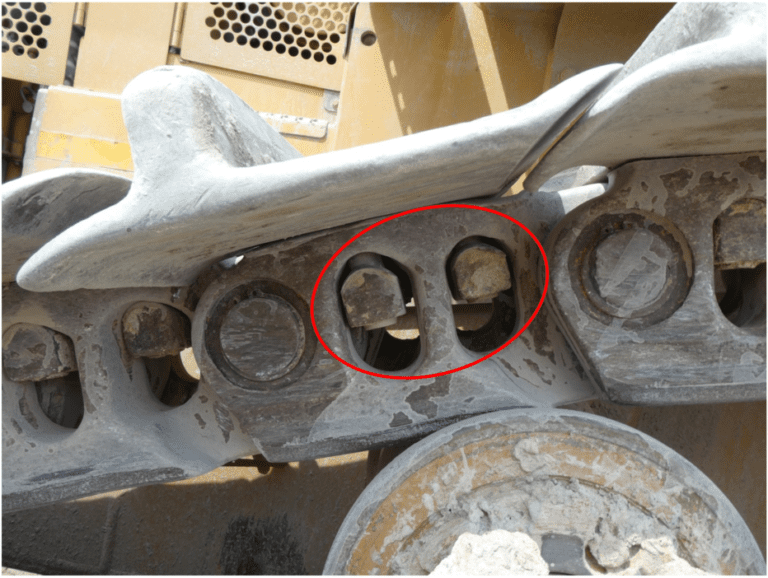

Don’t Miss the Small Stuff When Inspecting Undercarriage

Inspecting Undercarriage is not solely to measure components. It’s about creating a complete picture frozen at a point in time over the life of the Undercarriage. This picture must use images abundantly. Images replace a thousand words. Other points of interest help to complete the picture such as highlighting: Loose

Obtaining Maximum Life From Your Undercarriage Components

The art of undercarriage management is achieving as close to 100% wear from all components on the system simultaneously. This means that each component; whether rollers, idlers, sprockets or chain; are all wearing so that when the first component reaches 100% worn, all of the other components are as close

Inspection Forecasting – Knowing What and When

Every Inspection will identify the current wear of the components along with possible actions to rectify the wear profile of the components. The aim of the target wear profile is to achieve the maximum possible life from all the components on the undercarriage system, thus maximising your ROI. Regular

A Focus On Reducing Cost Per Hour

In reposonse to high demand from many mining customers TrackTreads has now incorporated GET, Dump Bodies and other wear surface management tools into the same package and offering as the Undercarriage solution. This gives inspectors the ability to inspect the following wear surfaces; undercarriage, dozer and grader blades, excavator

Bucket, Dump Body and Boom Inspection Tools

TrackTreads recently released their latest software toolkit for measuring and managing the wear surfaces in Dump Bodies, Buckets and any other wear material needing to be managed and measured regularly. Users of the Undercarriage Management System will find the system and layout very similar and accessible in the same web

Undercarriage Management – Increasing Your ROI

Investing in the implementation and use of undercarriage inspection management software needs to provide a return on investment. Undercarriage can make up more than 50% of the maintenance costs of a machine. Therefore managing undercarriage has the potential for large savings. How is the ROI measured:- Time and accuracy

Managing Undercarriage Across Different Brands Of Machinery

Look at any jobsite whether construction or mining, and you will notice a mixture of equipment brands. Every Mine-site or construction jobsite faces the same problem; how to manage the undercarriage inspection and condition information across the different brands of machine in their fleet. TrackTreads have addressed this by including

Track Inspection Data Rapidly Converted Into A Quote

TrackTreads have recently updated the Undercarriage Inspection Management system to enable quick generation of a quote for repairs or part replacements. Inspectors can now perform an inspection on any make or model and deliver to the customer, both the inspection report and a formal quote within minutes of completing the

Undercarriage Inspection Management System to Support Key Undercarriage Purchasing Decisions

Any decision to purchase replacement undercarriage components is governed by 3 main factors: Cost, Performance and Availability Cost –In construction, most undercarriage purchasing decisions are based on cost, for good reason. Equipment is costed to a contract or job and life expectancy is normally not a consideration. Cost per

How Often Should Undercarriage Be Inspected?

Undercarriage on dozers, mining excavators and shovels is an expensive commodity, equivalent to, or more than tyres and rims if not properly managed. This is a significant cost and as demonstrated in a previous article, can be north of $40.00per hour of operation. Such an expensive commodity as undercarriage which

How useful would historical data be when conducting an Inspection?

How useful would it be to have the previous inspection results displayed when completing the current undercarriage inspection and measurements. The screenshot seen below is the TrackTreads mobile application used for recording undercarriage inspection results in the field. The previous inspections results are displayed below each component including the tool

Training to become an Undercarriage Inspector takes real grit

TrackTreads have now been providing undercarriage training to inspectors for the last 12 months. This enables customers with large tracked fleets and mine-sites wanting to manage their own undercarriage with the necessary skill set internally to be able to measure correctly and accurately. Many customers already manage their own tyres

Undercarriage Management is as important as Tyre Management

Undercarriage inspection and management is more complicated than tyre management, yet is just as important; and in some cases more important. Undercarriage consists of more parts, which means more points of possible failure. Good management and regular inspection of these parts goes a long way towards mitigating this increased complexity.

Undercarriage management for Mining Shovels

Mining Shovels are high impact machines, not just in relation to the work they do, but also by virtue of the impact they can have on your production timeline and your bottom line. For this reason, undercarriage management on these machines is particularly important. It is critical that you select,

Undercarriage management is not just a matter of inspection

Undercarriage Management is not just a matter of inspection Undercarriage maintenance costs can be as much as 50% of the total owning and operating costs of the machine. Managing these costs is not just a matter of reviewing historical costs in the management accounts. To manage the undercarriage with serious

Managing Undercarriage With Spreadsheets

Are you managing undercarriage data with spreadsheets? Do you spend lots of time preparing the data so that you can then manage and make decisions? If you do, you are not alone! The reason for this is simple! The tools for inspecting, measuring and managing the undercarriage inspection results are

Managing Undercarriage Can Save You Money

Undercarriage components can make up more than 50% of the operating costs of tracked machines over the life of the machine. This can amount to large dollars in operations where there are multiple tracked machines. Operators will typically want to obtain the maximum life from the undercarriage components in the

TrackTreads Website Launched

Welcome to the new TrackTreads website! We’re excited to start filling it with interesting articles, case studies and news related to how our application can help you save thousands through management of the maintenance on your machines undercarriage.