News

Recent News

Pillar 1: Proactive Undercarriage Forecasting Starts With Accurate, Consistent Measurement

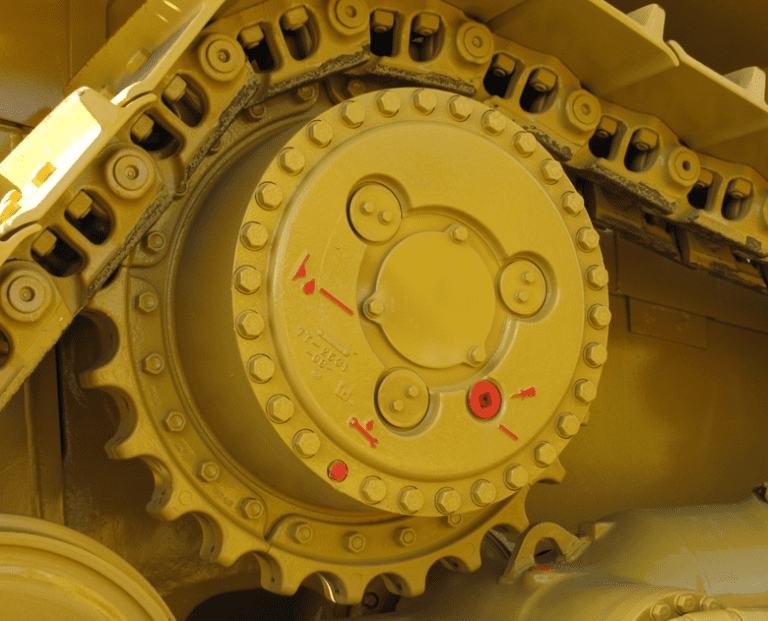

1. Use the Right Tooling Accurate measurements depend on purpose-built inspection tools designed for track chains, rollers, idlers, and shoes. Depth Gauges, Callipers, ultrasonic tools, and Bluetooth-enabled instruments ensure precision and eliminate human-error. Contact Help@TrackTreads.com for tooling requirements 2. Apply Correct Measurement Technique Even the best tools are ineffective without

Turning Undercarriage Wear Measurements into Data-Driven, Measurable Savings

Undercarriage Management is not just inspection.It is the conversion of physical measurements into decisions that extract maximum component life and eliminate unnecessary cost. Measurements alone do not create value.Decisions driven by those measurements do. The process is simple to explain, but powerful in practice: This is how undercarriage becomes a

Valuation of a Used Undercarriage Track Frame

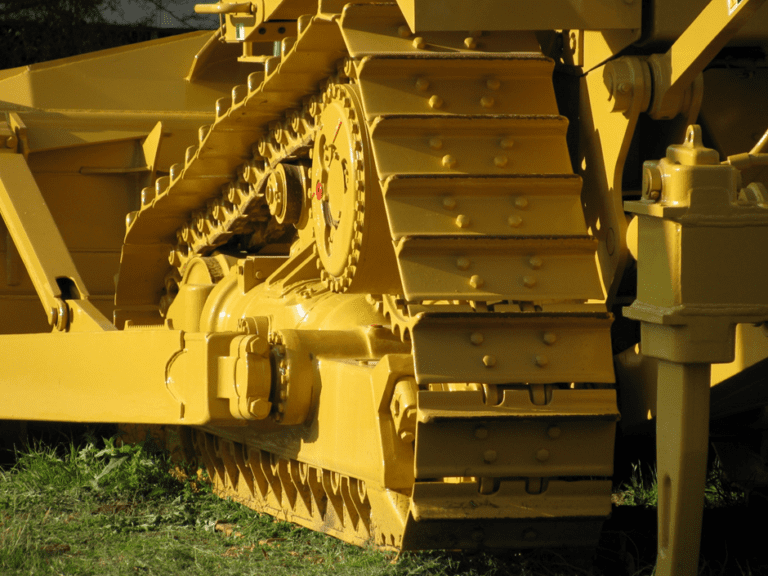

Undercarriage Track Frames represent a significant capital asset within heavy equipment fleets. Their total installed cost comprises both the rebuild cost of the frame itself and the value of the undercarriage components fitted to it. Once installed and in operation, the frame progressively wears, depreciates, and is subject to fatigue

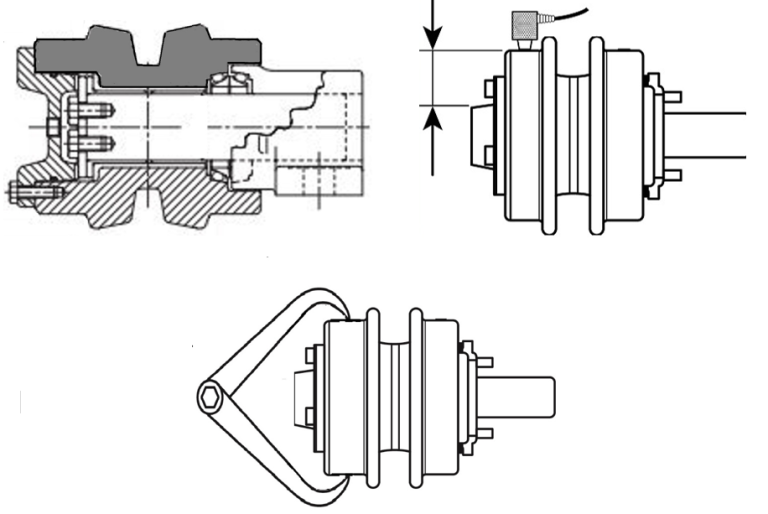

Measuring Upper Rollers in Undercarriage Systems for Accurate Results

Accurate measurement of undercarriage components is essential to correctly assess wear levels and to provide a reliable estimation of the remaining component life. Carrier (or upper) rollers present particular challenges in this process. The internal surfaces of the roller shell are machined with varying shapes to accommodate both the roller

Beyond Budget Life: Enhancing Decision Quality Through Condition Monitoring

Every machine is built from components, each with a different service life. Traditionally, life is tracked against a budgeted target, but this often fails to reflect the true condition of the component. By combining actual operating hours with condition-based inspections, Asset Managers gain a more accurate picture of component life:

Use the Power of Data to Increase Profitability

Undercarriage inspections are critical to maximizing the life and return on investment of your equipment. Machines that are not regularly inspected typically achieve only 75% of their potential life. Take a large dozer as an example: That’s a 25% improvement in cost efficiency, saving $62,500 per undercarriage set. By using

“Managing Millions: Why Undercarriage Inspections Matter More Than You Think”

Reliability Engineering plays a critical role in modern maintenance strategy, helping to safeguard the significant investments made in heavy equipment. One key element is the disciplined application of preventive maintenance routines—especially Oil Sampling, which has become a non-negotiable practice across most maintenance teams. Twenty years ago, it was not uncommon

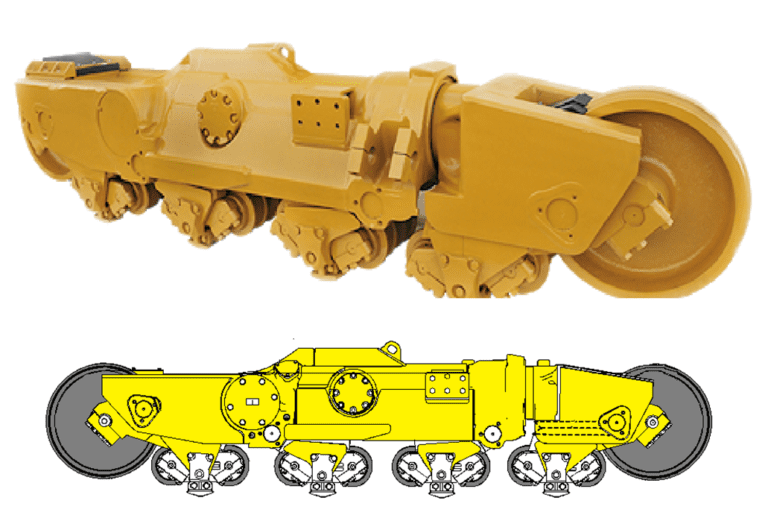

Tread Carefully: Measuring Hydraulic Shovel Undercarriage Life Accurately

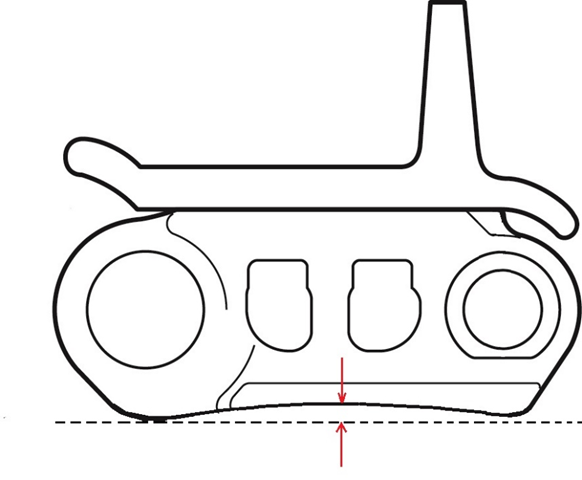

Tread Path Depth and Pitch Elongation are two critical indicators used to assess the current wear level of a Hydraulic Shovel’s undercarriage, and more importantly, to estimate the remaining service life of its components. Tread Path Depth can be measured in two ways: While the top-of-lug method (Figure A) is

Stay Ahead of the Shortages: Strategies for Undercarriage Component Security

Keeping the Dozers working through Turbulent Times

Revealing Hidden Value in Your Undercarriage Data

Undercarriage inspection data provides a wealth of valuable insights that can drive smarter maintenance decisions, improve fleet reliability, and optimize costs. To maximize its impact, this information should be organized into three key categories: 1. Current Condition – Snapshot of Fleet Health This section captures a current-time snapshot of the

From Data to Information: The Story Behind Every Undercarriage Image

Images captured during Track Inspections do more than just illustrate—they help tell the full story of undercarriage wear. Every inspection aims to uncover how Track Parts are performing over time, and images are a vital tool in revealing that narrative. Photos of the Track Parts serve as a visual check,

Release Notes for Version 9.2

Undercarriage Planner screen added to the tool set – accessible from the Undercarriage Menu. Includes the following screens Forecast Screen tab – on Interpretation screen Undercarriage Actions Screen Inventory screen Cost Calculations in Undercarriage Equipment Audit Trail Other Undercarriage Issues Buckets, Trays, Frames General

Reduce Frustration with Undercarriage Management using Data-Driven Decisions

Undercarriage management is a complex and often misunderstood science, requiring specialized knowledge that is in short supply. Many organizations struggle with: The Solution? Data-Driven Insights. With a data-driven approach, you gain a clear, real-time view of your undercarriage condition, enabling: TrackTreads can help you take control of your undercarriage management

Maximize Dozer Performance: Don’t Overlook the Push Arms!

Dozer Blade Push Arms are important too

Maximizing Track Life: The Power of Distance-Based Forecasting

Distance Based forecasting for Undercarriage Life and Replacements removes inaccuracies caused by: Idle Time Distortions and machine Speed Variations

Why UC Swing Chains & Frames are critical for Dozer Reliability

Optimizing Swing Chain and Frame Management in Mining Operations Swing Chains and Frames are critical components in mining operations utilizing a fleet of dozers. To maintain optimal machine productivity, it is essential to ensure that worn-out chains and frames are promptly replaced, repaired, and tracked efficiently. Ensuring Continuous Machine Operation

Using Technology for Management of Buckets and GET

Managing the wear performance of buckets and their individual components in large fleets of wheel loaders (Above or below ground), hydraulic shovels, and electric rope shovels is important for optimizing operational efficiency and improving costs in mining operations. Each bucket is made up of multiple individual components including Floor, Sidewalls,

The Power of Undercarriage Data

There are several ways in which undercarriage data is collected. On its own, the data points will not mean a lot, but all together and once analysed, this data forms a powerful roadmap for end users, suppliers and manufacturers alike. The more data that is collected, the greater the power

6 Tasks lead to Good Undercarriage Management

Performing 6 tasks will lead to long term costs savings and increased competitiveness in the market The reason to perform these tasks is that Undercarriage components undergo extra machining and surface hardening in order to have the necessary wear resistance. This costs more and thus undercarriage maintenance costs will be

F1 and Cane Harvesters use Data to drive Maintenance Decisions

Sugar Cane Harvesters need to be operational 99% of the time during harvest season. Each mill uses a fleet of at least 30 of these machines, and sometimes up to 1000 pieces of equipment including tractors and trucks. These harvesters are complex, running on tracks and hydraulic systems. To ensure

Managing Undercarriage Off the Machine

TrackTreads provides a systematic process to help keep the machine running as the Chains and Frames are replaced on the machine to and from inventory. Each frame and chain is tracked to provide traceability of work performed and performance data on life achieved in total hours or distance achieved. Warranty

5 Simple Steps to save money on your Dozer Undercarriage

5 simple steps can ensure significant cost savings with you Fleet Undercarriage Management

Undercarriage Inspection Tool Kit

Another Undercarriage Inspection Kit heads out to a team of cts (Custom Track Service) inspectors on a Minesite in Australia Items include: 1. Ultrasonic Tool and Probe 2. Depth Gauge 3. Tape measure 4. Ruler 5. 2 X Calipers 6. String-Line 7. Scraper TrackTreads provides the Toolkits, Software and Training

Share the Love with your Track Frames

Track Frame condition is just as important as Track Components

Distance. An Accurate way to measure Undercarriage performance.

Component life measured in distance travelled is the only accurate measure of performance

Reliable Undercarriage Strategy to unlock the value of your undercarriage investment

Reliability Engineering can unlock the value of your investment in Undercarriage

Study of Benchmarks for Undercarriage Management

Last year, we were asked by and Asset Manager seeking insights into the average worn percentage of undercarriage components at their end of life. His aim was to establish key performance indicators (KPIs) to measure his team. This inquiry instigated numerous deliberations regarding the definition of average up to exemplary

Distance used to measure Undercarriage Component Performance

Managing Undercarriage Components based on distance travelled is a more accurate method of determining their life performance

Look after your teeth, as an investment.

Treat your teeth like an investment to get a favorable ROI

Track Frames also need the love

Undercarriage Track Frames should also be inspected. This will not only determine their condition, but will forecast when they will need to be rebuilt.

Training for Tracked Machines: TrackTreads’ Response to Changing Market Needs

The trainers getting field experience

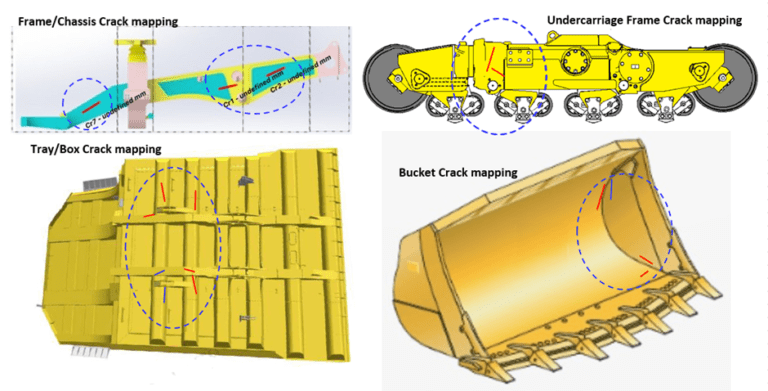

Inspecting and recording cracking on Mobile Field Equipment using a mobile

Cracks occur any many field equipment components. Management of these cracks ensures that catastrophic failure is avoided. Capturing crack data electronically provides some immediate benefits. There are 4 main steps covered for digitizing crack management. Field Inspectors capture, using mobile phones or tablets, the precise position of the crack on

TrackTreads Wear Management System

Wear Material comes at a higher cost because the components include extra elemental inclusions and further heat treatment in the hardening process. To gain the full benefit from these components requires achieving a full useful life. Any accelerated wear on the component will lead to a shortened life span and

Managing Undercarriage significantly reduces the cost of ownership.

Managing your undercarriage components reduces your cost of ownership since the components are more likely to live a full productive life.

Scalloping causes more than an uncomfortable ride

Scalloping is where the middle of the Link rail becomes hollowed out. This increases the vibration as the chain moves over the components and can lead to a very uncomfortable ride! Scalloping can be caused by a number of factors: – Idler Rise Heights are provided within the TrackTreads system for

Release Notes 8.9

ROPE SHOVELS Web – Small adjustments to screens to improve user friendliness. Reports – Rope Shovel Report – Layout Changes DOZER UNDERCARRIAGE Web – User Preferences – ability to move Inspection and Jobsite comments entry on the mobile. Web – User Preferences – Ability to set Component Inspection Order Web

The Value of Thermal Images in CTS (Custom Track Service) Inspections

The art of managing undercarriage is the early identification and then rectification of accelerated wear in the components. Inspecting and measuring these components, and then comparing the results with previous inspection results allows a comparison of the wear rates. Ideally the components should be achieving between 100 and 110% wear

Use Undercarriage Inspections to fight the impact of inflation

Track Inspections, known as cts inspections or custom track services, serve a number of purposes, but a few of the more important reasons are: In the image below, the budget life, of the undercarriage components for a large Dozer, is 8,000 hours, and the cost of replacing the undercarriage is

Managing Swing Track Chains in the yard

Chains must be able to be tracked from cradle to grave. In any mining environment, chains needing maintenance, whether it’s a regrousing of shoes or a pin and bush turn, will need to be taken off the machine and placed in the yard, ready to repair. To keep the machine

One System – One purpose – saves time

A single Mobile App. Operating remotely, allows inspectors to focus on specialized areas of Track, Blade and Bucket GET inspections as well as any other area requiring measuring and observations. Wear material on the components being measured includes surface hardening and treatment, hence the increased cost. Inspecting and managing these

Condition Monitoring Inspections should drive Maintenance Activities

Managing Equipment and Components is a tricky business. Condition Monitoring Inspections provide a solid basis for identifying and scheduling maintenance activities: – In contrast, the most expensive way to manage equipment is to fix the machines when they break down. By this stage, the components have failed and there will

Key Performance Indicators for Undercarriage Management

4 Key Measures for Effective Undercarriage Management 2. Wear Rate Performance 3. Lost or Scrapped Wear Material 4. Number of Maintenance Interventions over Track Life

A Testimonial of performance lies in the numbers

Marketing the benefits of your Buckets and Trays can be strengthened with numbers of actual performance from the field. The bucket or tray has a certain capacity, but the difference between competitive products will come down to:- The above numbers can only be gathered by continual inspection and management of

Actionable Tasks keep your undercarriage turning.

There are 3 main groups of tasks required to Manage Undercarriage effectively! Group 1: Collecting the field undercarriage inspection data Group 2: Reporting on Condition Group 3: Converting Actionable Items into Actions Integration with the Undercarriage Inspection System so that data flows seamlessly to the work order system is the

Future Forecast Date of Undercarriage Component Replacement driven by Data

Data driven decisions

Don’t let a Bottom Roller GUARD Hinder your Undercarriage Inspection

Getting around Gards covering Bottom Rollers

Undercarriage Inspections – learning the Basics

How do I start implementing an Undercarriage Monitoring Program? – TRAINING! As with all improvements once you have identified what to change, sometimes how to start moving in the right direction can be a little more challenging. Undercarriage inspections do not need to be complicated or difficult. Knowledge can be