News

Recent News

Release Notes 7.1

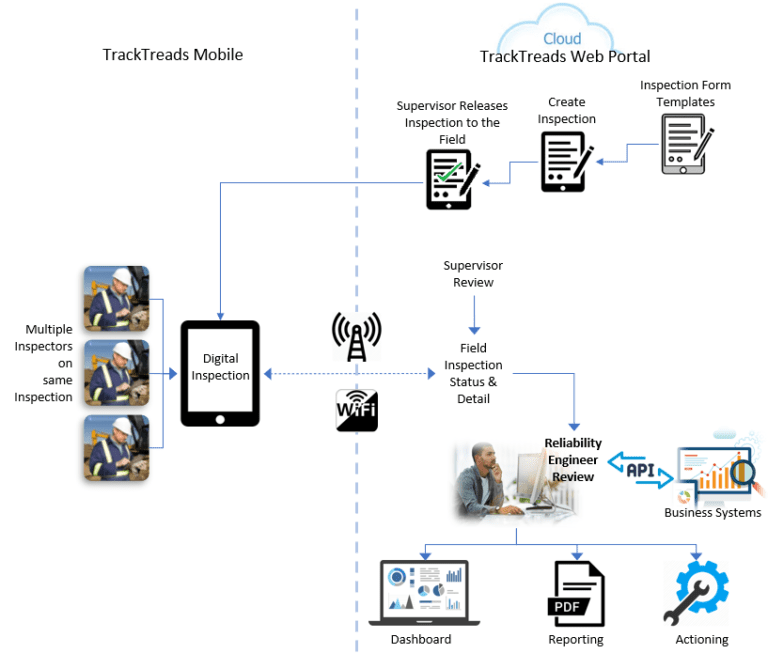

Digital Forms Until now the TrackTreads system for both Undercarriage and Wear surface monitoring of GET and structural components has been focused directly on measurements and evaluations of components and defined observation points. With new Digital Forms, you can now create custom forms that can include the existing observation points

Digitizing Field Inspections can produce big savings

Reliability Engineers carry the burden of scheduling maintenance tasks to ensure maximum production availability of machinery with minimum downtime for maintenance. The quality of their decisions depending on the quality of the data available. Digitizing Field Inspections can provide more data, quicker and more accurately. It does not stop there

The cost of Walking Too Far

Large Hydraulic Shovels and Rope Shovels are not built to walk long distances. Short distances is all they can do. The general rule of thumb is no more than 7% of the overall machine hours should be spent walking the machine. Take an example, our shovel aims to achieve 22,000

Managing Undercarriage is more costly than Tires

Tires are high-pressure vessels on which the wear is measured typically by measuring the depth of available tread with at least 3 points being taken across the face of the tire to provide a reasonable average. The overall condition of the tire will be inspected to identify any visible faults

Great Products should be flaunted with Testimonial Data

In this day and competitive environment, if you have a great product, flaunt it with a convincing argument! Demonstrate your argument with a testimonial of performance. This can be done in the following steps Investment in placing product in the field Monitoring performance of the product in the field through

Release Notes 7.0

Version 7.0 is focused on the Undercarriage system and adds variety of new setup options and report improvements. It also includes the ability to add multiple images to all component inspection records. New Chain and Frame Configurations When setting up your frames the system now includes the option to

Using Propel Hours to Forecast Residual Undercarriage Life on Shovels

Excavators, Hydraulic Shovels and Rope Shovels spend most of their time digging and loading. They are only required to move short distances to reposition themselves or to move to a new area of excavation. In the mining environment, most undercarriage inspections will utilize the machine hours to forecast the

Release Notes 6.7

Custom Evaluations We have now implemented a system where you can customise the evaluation percentages and letters for your undercarriage inspections. The traditional A, B, C and X system will still be used with default percentage ranges for each, but you can now customise these on a per site customer

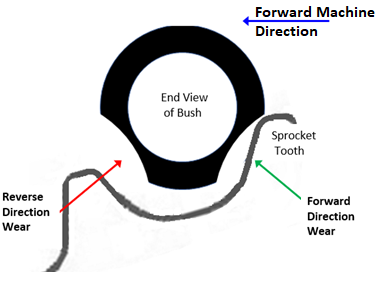

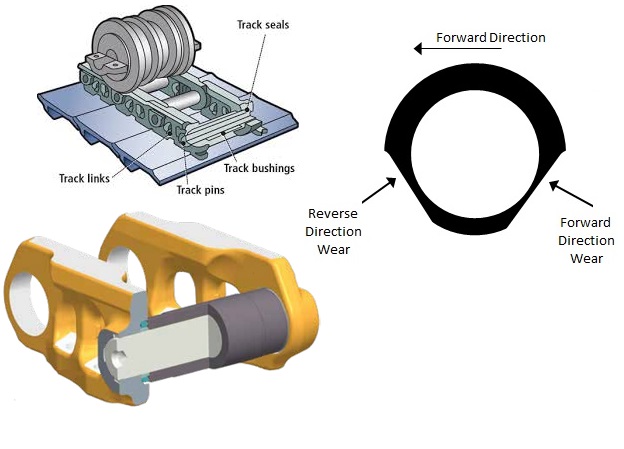

Ensure Chain is Installed in correct Direction to avoid quick destruction

Undercarriage Chain is built to operate in a specific direction of motion, this is the forward direction in which the machine operates under load. When the chain is installed in the incorrect direction, the reverse direction, will cause wear at 3 times the rate of the forward direction. It

Undercarriage Idler Failure can be detected to avoid further Damage and Expense

The Front and Rear Idlers on an elevated sprocket machine are effectively the spreaders for the track chain. The idlers keep the chain reasonably tensioned and guides the chain as it rotates. The track chain is essentially a rail that is laid down and picked up again in a continuous

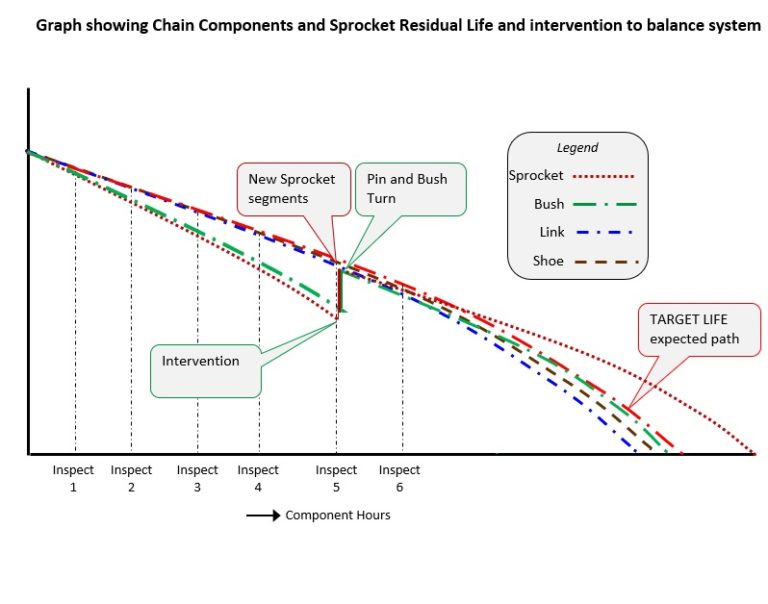

Bush Turn Budgets ensure Turning of the Undercarriage Bushes are not Missed

On the non-rotating sleeveless bushes, the wear on the bush is typically on only 180% of the bush as shown in the following diagram. Bush Life before Turning The speed of wear on the bush will be determined by various factors

Independent Undercarriage and Asset Wear Monitoring Systems

Technology is everywhere today, being used to increase efficiency and reduce costs. Undercarriage Management is no different and any customer operating tracked machines is using Undercarriage Management and Asset Wear Monitoring Systems to track the condition and performance of their components and plan maintenance activities. OEM’s or Manufacturers and their

Release Notes 6.6

Introducing Thermography Inspections TrackTreads has been working with IIAT to include thermographic inspection data in the system and this is now available. As well as thermographic measurement of all standard undercarriage components, the system also allows for the creation of any additional components where thermographic imaging is used to assess

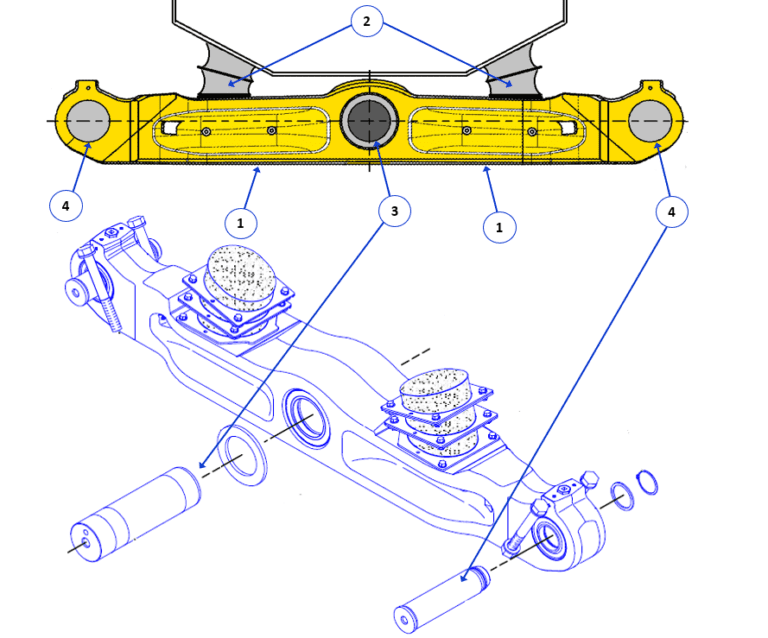

Failed Undercarriage Frame components can seriously impact the costs of your undercarriage

Failed Undercarriage Frame components can cause untold damage to the undercarriage, reducing their life expectancy substantially. Any reduction in expected life increases the cost per hour. Looking at our first example in a series on frame components, is Major Bogie Pin failure or collapse. The bogie carries 2 track rollers

Scalloping of Undercarriage Links causes significant downstream costs

Scalloping is a dangerous condition leading to significant downstream costs if not identified early. So what is scalloping? Scalloping of the links is where the midsection of the link becomes hollowed out. As the hollowed-out link /rail passes over each roller and idler, it creates vibration. The larger the scalloping,

Release Notes 6.5

Along with bug fixes and small enhancements the 6.5 version has 3 major pieces; SSL security – Security has always been a priority and with this version we have moved all TrackTreads systems to use HTTPS. This means all data transfer is encrypted for added privacy and security. Google has

Continuing Operations under Covid-19 lock-down

Are you trying to manage your continuing operations under the Covid-19 lock-down? Have you considered the potential impact of supply chain disruptions on the operation of your fleet? Could part of your fleet end up being parked due to lack of parts? How long will this continue? Many of these

Undercarriage Bush Turns can save money

Managing Undercarriage Bush Turns to save money requires skill, inspection data and systems to accumulate the data. Under Covid-19 conditions, many companies operating tracked fleets may need to manage this in-house, since supplier inspectors are not currently able to visit the machines. Technology can now provide solutions to this challenge.

Release Notes 6.4

BIG NEWS You can now fully setup machines in the Mobile App and have them instantly synced to the cloud if you have an internet connection. You can fully configure the components and get wear percentages instantly on new machines. You can even setup new jobsites directly from the Mobile

Release Notes 6.3

Undercarriage Enhancements This release includes a bug fix for creating new machines on the mobile app. It also includes additional graphs and inspection history on the Equipment Details Screen Our commitment to providing the best systems we can depends on you. We are here help you get the most out

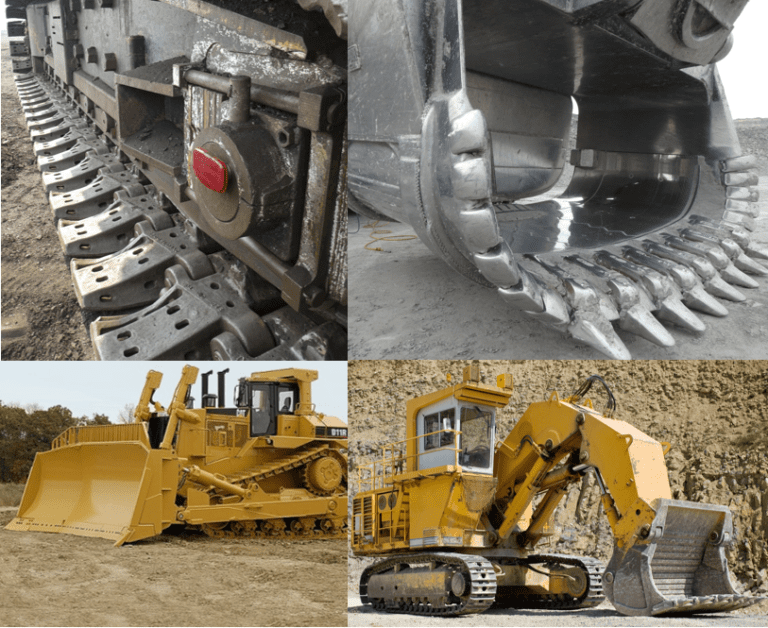

At up to 3 times the cost of the engine, are you giving your undercarriage the attention it deserves?

Every earth moving operator will faithfully ensure Oil Samples are taken to determine the internal health of the engine, transmission etc. It is normally part of the warranty requirement on the machine or those components. Every Oil sample analysis report is examined carefully for any signs of potential failure to

Release Notes 6.2

Undercarriage Enhancements Rope Shovel reports have been a big focus of this release including the addition of multiple Crawler Frame Guides. We are continuously improving language handling and your custom reports are now available in the language of your choice. Component images are now more customisable so they more accurately

The Importance of setting “Target Life”for Undercarriage Components

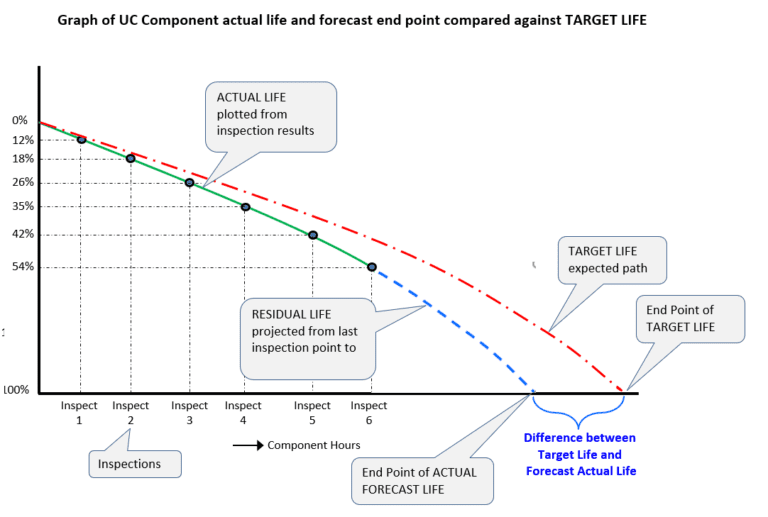

Undercarriage systems are made up of multiple components. Each component has its own distinct life span. The challenge is to ensure the entire set of components achieves the greatest possible life, (The “Target Life”), for the system as a whole. This will depend on the weakest component. The individual components

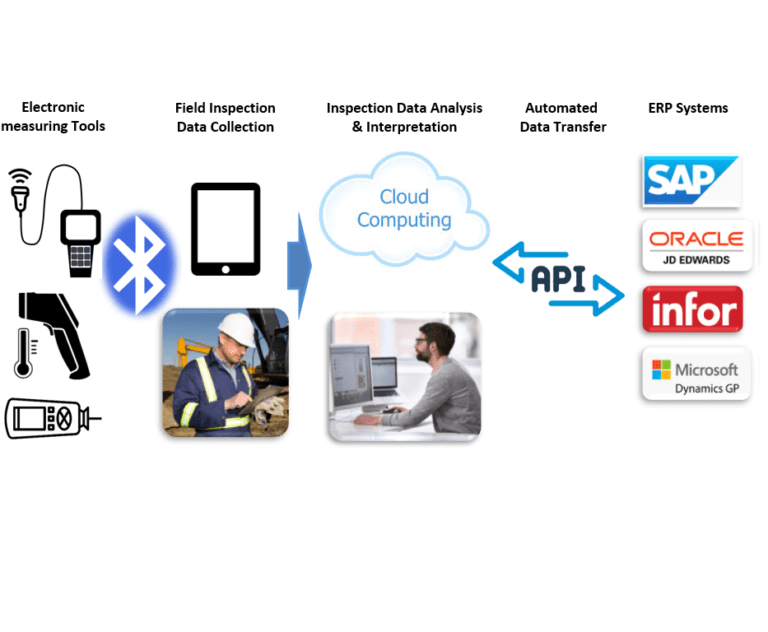

Digitization of Inspection Management and the benefits it brings

Digitization is the process of converting a manual process into a digital format. There can be many reasons why this is done not least the following:- Increase the accuracy of data collection Increase the volume of data collection such as images, comments and calculated results from readings. In some cases,

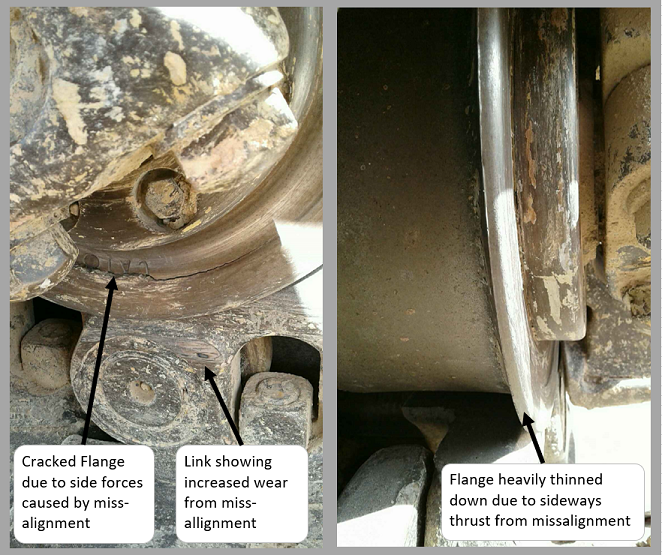

Avoid Spending Big on Bogies by Inspecting the Bogie Hardware as part of the Undercarriage Inspection

Major Bogies carry the load of the machine on the rails (Links) and any miss-alignment, wear or damage can create large costs. Identifying problems on bogie components before they fail can reduce this cost significantly. Regular inspection should be completed, and what better way than to include it within the

Overcoming Mine-Site Technology Adoption Challenges

Overall mining productivity has risen 2.8% per year from 2014 to 2016 according to McKinsey research. These improvements will become harder to sustain with new challenges facing mining companies (costs of labour, environmental concerns, depth of mines etc..). But technology can enable the continuity in productivity improvements. The challenge facing

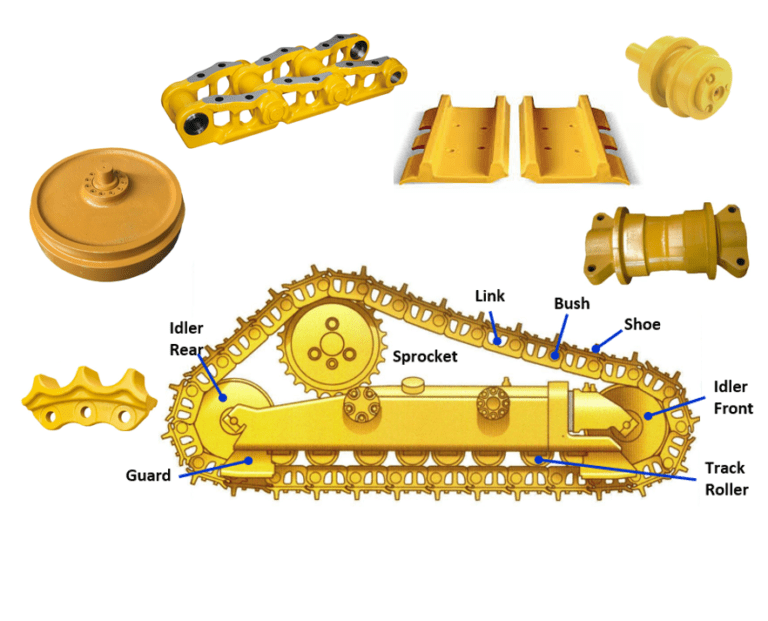

Reduce potential downtime by inspecting ALL Undercarriage Components

The Undercarriage Equalizer Bar performs a critical undercarriage function, so identifying any potential problems that can be handled at planned maintenance stoppage would be ideal. Things to look for are: – Equalizer Bar damage – check that there is no damage or cracks in the bar itself Rubber Pad condition

Release Notes 6.0

The v6.0 release includes a number of Undercarriage bug fixes and improvements, with the biggest changes in this version being the release of the new Mobile App for Android. For details regarding the new App please contact us so we can assist you with the installation. There are also additional

Undercarriage inspections are no silver bullet

Undercarriage Inspection software is not the silver bullet to Undercarriage Management but rather an enabler. It is a highly specialized system to evaluate a small but expensive part of the larger puzzle of tracked equipment condition and maintenance management. It should become an integral part of every mine-sites future technology

The cost risk of falling behind.

Undercarriage inspections are the norm whether for a mine-site, construction fleet or in Sales and Service of Undercarriage components Mine-sites use the inspection data to plan their maintenance on the tracked machines and monitor their cost per hour Construction-Fleets use the inspections to monitor the condition of their fleet and

What Constitutes Undercarriage Management

Undercarriage components wear at different rates depending on a number of factors: – Working environment Condition of surrounding components Operator skill level Shoe selection Track Tension Maintenance regime The undercarriage is changing daily and the maintenance strategy requires balancing the above factors as best as possible to achieve the TARGET

Undercarriage Management – What is the cost of doing nothing?

If you have a fleet of Heavy Equipment that includes Tracked Machines, there will be a line item on the income statement that includes the cost of replacement undercarriage components. The question would be, is that number fair and reasonable? Managing your undercarriage would be one way to determine if

Undercarriage Inspections give you a deeper perspective of your marketplace

Undercarriage inspections carried out regularly on tracked machines by service providers provide a wealth of information about the marketplace. Some of the information to be garnered for a particular territory using the inspection data: – Number of machines in the territory by brand and model Number of new machines introduced

Step up to any tracked machine and inspect the undercarriage

The TrackTreads Undercarriage system provides inspectors with a unique opportunity to inspect any brand of tracked machine and its undercarriage using the OEM wear limit specifications. This provides Fleet managers with 3 distinct unrivalled opportunities A single portal to view the condition of undercarriage across the fleet Enables Fleet managers

Saving Money by Using Technology to efficiently collect Field Inspection Data

Mine-sites perform regular inspections in the field on mobile and fixed equipment. Results are typically written on paper forms or captured on spreadsheets and then re-entered to the ERP system at a later stage once back in office. The TrackTreads system can save both time, money and accuracy by using

The Hidden Costs of Undercarriage

Undercarriage repair and replacement cost a bucket load of money and maintenance crew are hard pressed just to stay on top of the current maintenance let alone spending time inspecting undercarriage. Knowing the true cost of intervention and replacements may lead to a different view on this. In a prior

TrackTreads achieves a new milestone, helping our customers exceed their undercarriage sales budget

TrackTreads reached a new milestone helping one of our customers achieve 125% of their sales budget. Undercarriage Inspections highlight undercarriage components needing repair or replacement, providing a ready source of revenue. Our customers utilizing the TrackTreads Undercarriage Inspection system to inspect any make or model of tracked machine, utilizing OEM

Inspectors can walk up to any tracked machine and measure the Undercarriage

Every fleet owner of earth moving machinery has multiple different makes and models of machines. Machines are acquired to match their strengths to the specific requirements of the project and ensure cost effectiveness. This does of course create a headache for the customer when it comes to measuring the undercarriage.

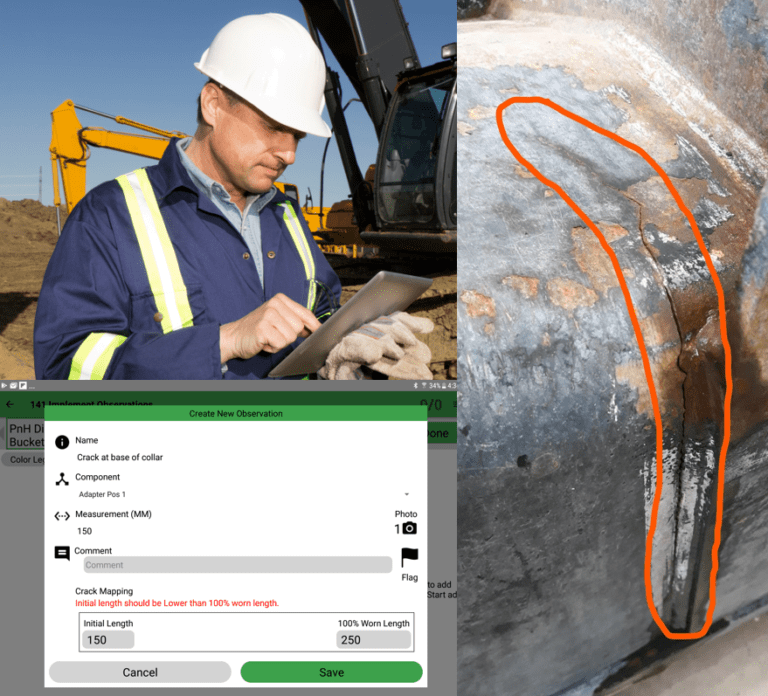

Cracks in Equipment Chassis can become Catastrophic Failures

Regular scheduled inspections should enable Cracks to be (a)Identified, (b) measured, with limits set for maximum length and then (c) scheduled for repair by a specified date depending on the propagation rate and maximum allowable length. Images and comments help to make the task of creating work orders with specific

Comparing Performance between different manufactured components

Undercarriage components are high wear and large replacement cost items. Succeeding in this market means proving the performance of the product. This is where it often gets twisted since to provide a true comparison of performance; “apples versus apples”, requires: – Selecting the correct component for the environment – testing

Testimonials help sell product

Undercarriage and GET are high cost, fast wearing parts on any machine. The result is that there is a lot of money associated with the replacement of these components, and many options available in the market. Customers purchase product based on price and product performance. Price is easy to calculate.

2 in 1 Bucket, Blade and Undercarriage Inspections in a single app saves time and money

High Wear Components need to be monitored on any quarry or mine-site as they chew up heaps of money. Downtime for repairs or replacements needs to be planned while also monitoring the actual true performance of these components in cost per hour or tonne. This challenge has been made easier

New Frontiers for Wear Surface Management

Equipment Management is an ever-evolving science with existing frontiers being constantly broken while new ones are being set. One of those frontiers is in Wear Surface Management and more particularly Undercarriage and GET. Companies operating heavy gear are spending large dollars on Undercarriage and GET. The question on both end

Undercarriage Inspections are not just about undercarriage

The best sales opportunities for undercarriage come from visiting the machine and performing an inspection. However, it does not need to end there. Inspectors visiting machines for undercarriage inspections can provide extra value to their customers by looking at the entire machine to see what else is obviously needing repair

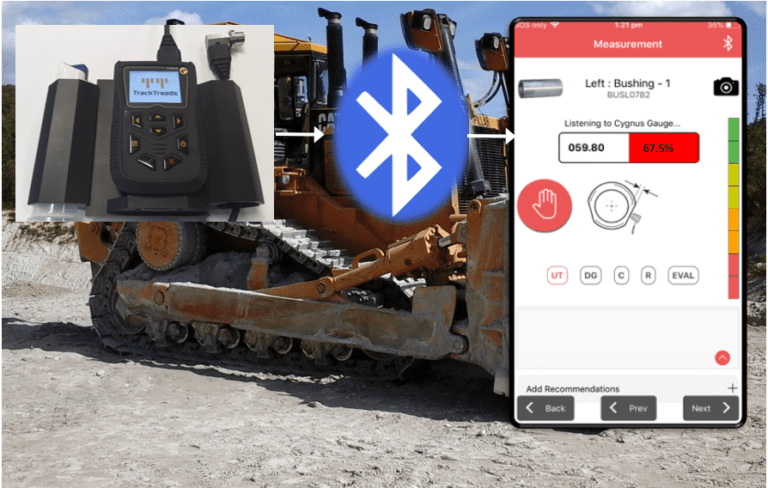

Undercarriage Inspections on iPhone App with Bluetooth connection to Ultrasonics

For all our Apple fans, we at TrackTreads have released the Undercarriage Inspection App on iPhone with BlueTooth connectivity to the Ultrasonic Tool to make recording measurements seamless. Contact is if you need assistance on downloading and using the app with the Ultrasonic Tool. We are always available to help

I Love my Job – TrackTreads Onsite Undercarriage Inspection Training.

This month during our TrackTreads onsite Undercarriage training, I visited some wonderful new people as well existing colleagues in the United States and Canada I would like to thank everyone who participated in the training from Texas, Kansas City, Mississippi, Arkansas, Tennessee, Wisconsin, Indiana to Alberta. I would also like

No substitute for Undercarriage Inspections

In our travels we have yet to find a substitute for Undercarriage Inspections. This is the single most effective way to manage and monitor the performance, condition and cost of your fleet of tracked machines. There is no alternative, and for those salesman looking to help their customers manage these

Measuring and Managing GET and Bucket performance

Would inspecting GET and Bucket Wear Surfaces provide value for both maintenance management and condition monitoring purposes? There are some compelling reasons to monitor buckets and GET Production can be affected when the primary loading tool is down to some failure of a bucket, be this missing teeth/adaptors or cracked

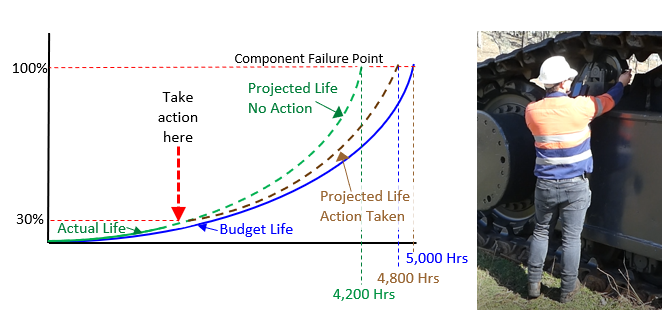

Early Intervention to achieve Budgeted Undercarriage Life

The Undercarriage Components installed on your equipment are expected to achieve a certain budgeted life. However, this is not where the story ends, because the components will not achieve their budgeted life if they are not properly managed, and the only way to manage undercarriage components is to measure them.