News

Recent News

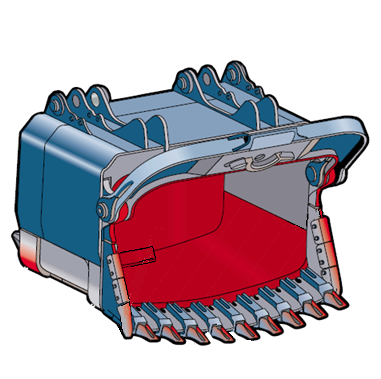

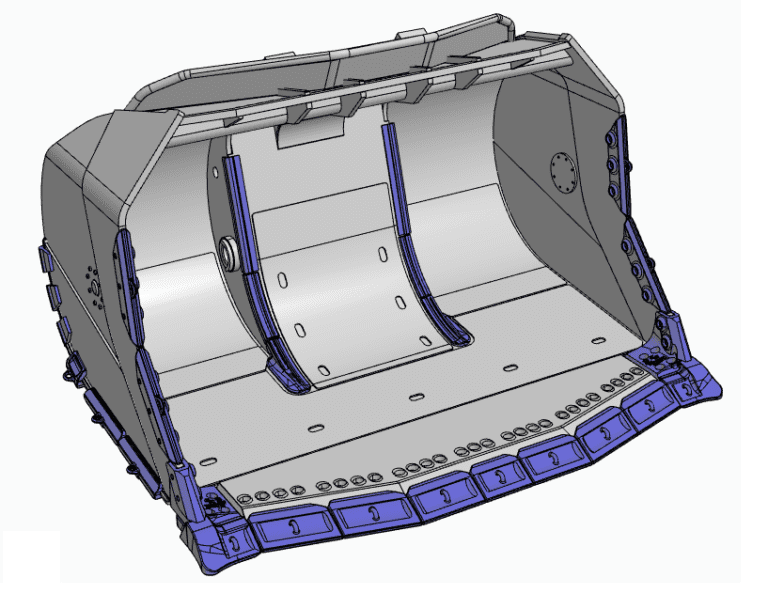

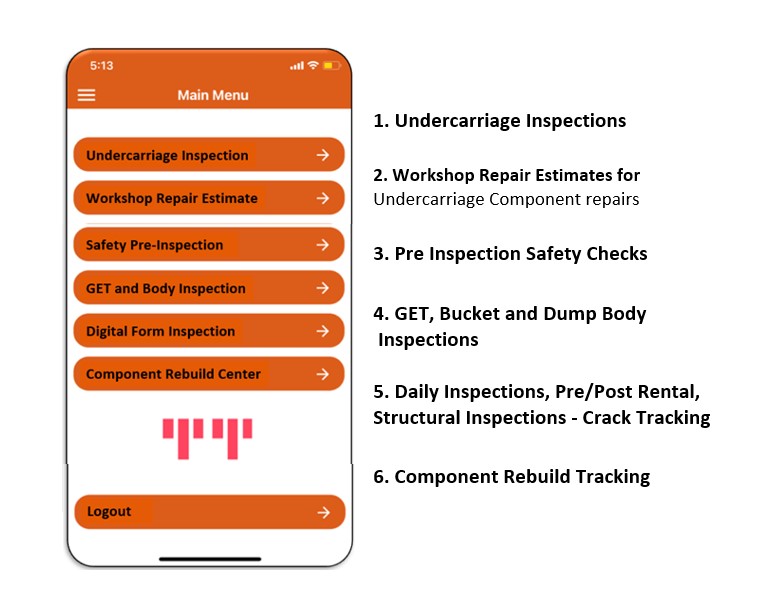

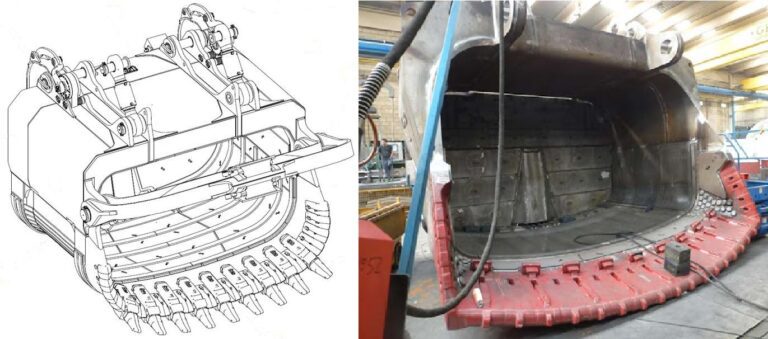

Underground Buckets added to TrackTreads Field Inspection Software

Inspectors can now perform condition and wear measurement inspections underground on their mobile device on GET, Wear Plates, the bucket core and attachment points for their underground buckets. The system will automatically forecast when the bucket needs rebuilding based on the wear percentage and residual life of the critical components,

Undercarriage Inspections give certainty to Maintenance Planning

In our business at TrackTreads we have many different customers each having their own reason to perform Undercarriage Inspections. There is however one common theme throughout which is to calculate the residual life of undercarriage components so as to plan for the next maintenance event. This calculation comes from the

Investing in Knowledge and Experience

The TrackTreads Support Team experiencing undercarriage inspections first hand

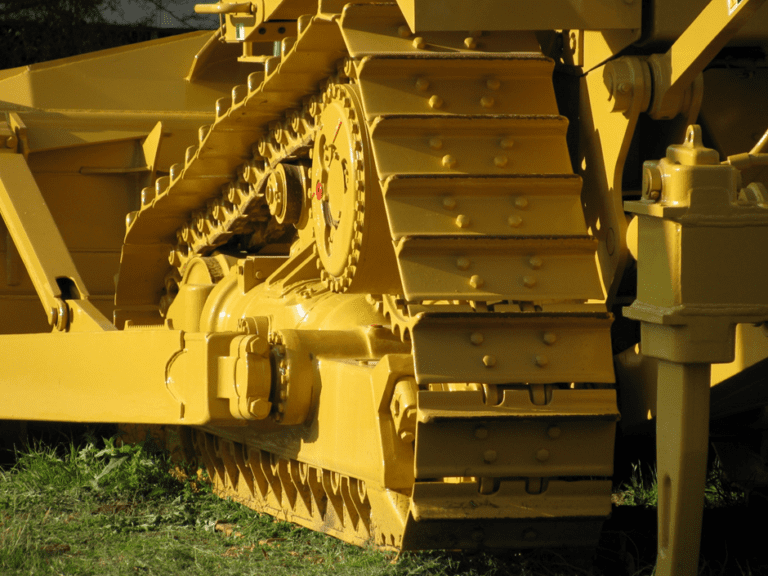

The Art of Measuring Track Shoes

Undercarriage Shoes provide flotation for the tracked machine on soft ground. The grouser bars provide the grip to enable to machine to propel forward. The grouser bar also provides a secondary function by adding structural strength to the shoe, the more grouser bars, the greater the shoe strength and the

Measuring Undercarriage Links

The Track link along with the bush are often the most important components to measure during a machine audit. The links can be measured using 2 of the available tools: Ultrasonic Tool and the Depth Gauge. Ultrasonic Tool The Distance F is measured using the Ultrasonic Tool. A small amount

Measuring Bushes during Undercarriage Audits

Pins and bushes can be one of the trickiest components to measure when performing a machine audit. Here are some tips and thoughts to help you.The Pin and bush on the undercarriage chain is subjected to wear from 2 directions depending on whether the machine is being operated in the

Achieving savings with Undercarriage Wear

Undercarriage, as a wear material on equipment is expensive due to the extra heat treatment and processing required to improve its wear properties. There are 2 ways to save money Avoid accelerated wear Utilise the wear material to its full available life Accelerated wear – is where the components become

Release Notes 8.4

This release was site specific and contained functions that were developed with collaboration with the customer. For further information – please do not hesitate to contact us on help@tracktreads.com

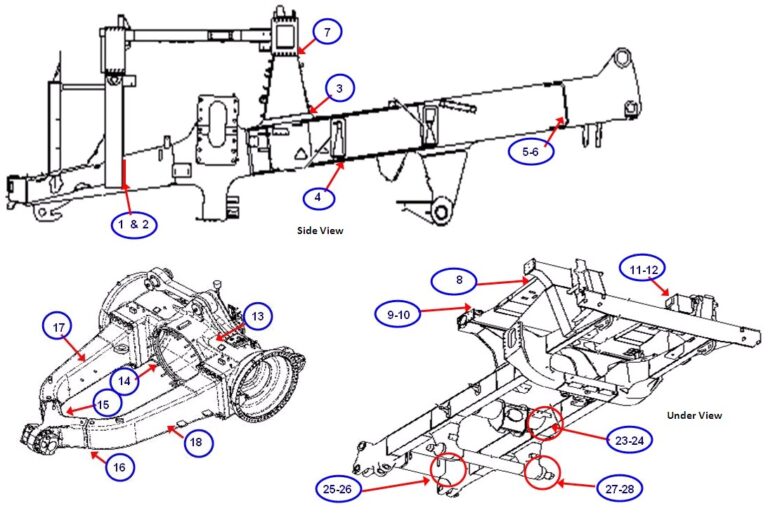

Undercarriage Frame Rebuilds – Grave to Cradle

Rebuilding worn out Undercarriage Frames provides each frame with a new lease of life. The frames arrive worn out and cracked. They are stripped down to the bare minimum Each disassembled part is measured, and assessed to determine whether it can be refurbished or needs replacing Cracks are identified, gouged

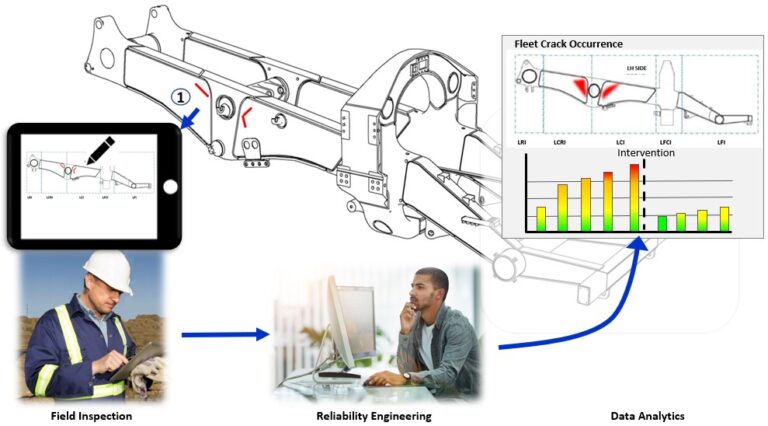

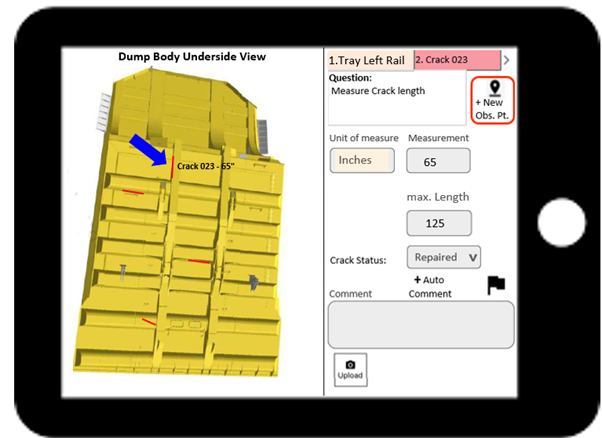

Crack Management on Field Equipment

The TrackTreads system provides “cradle to grave” Crack Management in Mobile Fleet Structures. There are 4 main steps covered in the management of these cracks Identification, measurement and setting of limits Field Inspectors capture, using mobile phones or tablets, the precise position of the crack on the structure by drawing

Sometimes is it good to go back to basics. 4 Basic Pillars of Undercarriage Management

Collecting Undercarriage Field Inspection data – Measuring the undercarriage component wear needs to be done regularly and accurately. Readings should then be supported by images and comments. Automatic calculation of % wear and the physical limits along with any prior reading history help the Inspector provide quality information. All this

How many $ Dollars lie in this boneyard of Undercarriage Components

A boneyard of Scrapped Undercarriage components tells a story of how the undercarriage components are managed. Components with life remaining = money lost

Getting value for your money in Undercarriage

Get value from your undercarriage by running it to between 112% and 120% worn

The most important Undercarriage Inspection of them all

The last inspection before the undercarriage is removed is the most important and provides a wealth of information

Field Structural Inspections help monitor patterns of cracking

Digitizing structural field inspections on mobile equipment such as trucks, shovels and dozers allows the collection and recording of the length and position of cracks on components common to the fleet of machines. Crack Length Measurement – Each following inspection will display the existing cracks allowing a further measurement to

Achieve Maximum ROI on your undercarriage for Tracked Machines

Increasing return on your undercarriage requires implementing and then maintaining certain basic steps as part of the normal business process. These steps require discipline but are simple to implement. Regular Track Inspections Undercarriage inspections should be performed regularly to measure components, calculate the amount of wear on each component, take

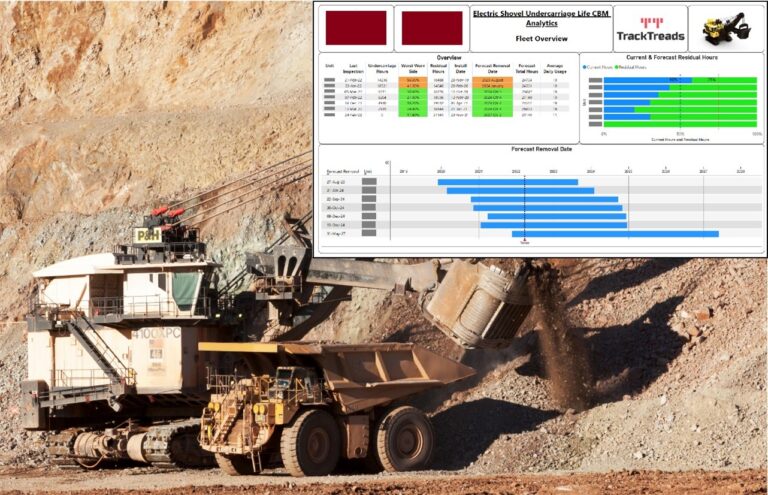

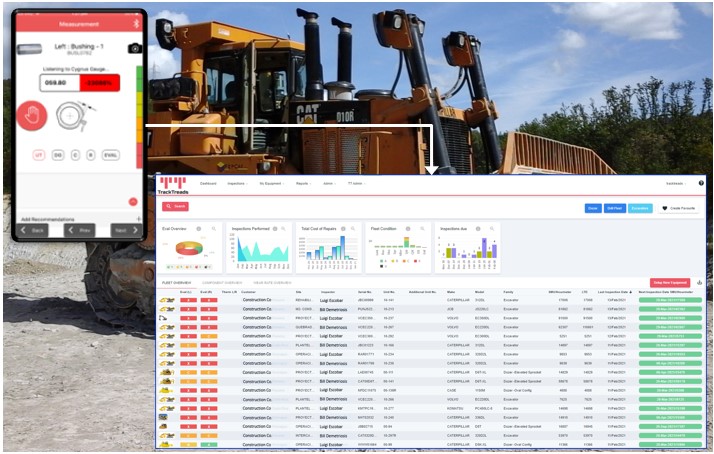

Crystalizing Field Inspection Data into a story for Management to Browse

In mining, large amounts of data is collected from the field continuously to the point of being swamped. The data will be on spreadsheets, paper inspection forms and many other formats. All this data is extremely valuable as it contains a story which management wants to read and understand. Extracting

Digitizing Crack Management

Digitizing Crack Mapping using digital tools increases efficiency of actioning the data, and allows trends to be easily identified

Financial Benefits of Managing your Undercarriage

Undercarriage is a high value wear item and can represent 50% or more of the maintenance costs on large, tracked machines. That represents a huge maintenance cost. Managing the undercarriage can therefore deliver large savings. There are several basic principles to be followed to unlocking these savings. TrackTreads Undercarriage and

Release Notes 7.9

Undercarriage Inspections User Contacts Screen – Uses not flowing through to the User Contacts screen – now fixed. A jobsite column has been added to help understand what sites a user is added to. Inventory Screen – repairing a component is now working in this screen. The inventory screen should

ROI – Using Undercarriage Management Software to obtain better life from your Tracks

Undercarriage can make up more than 50% of the maintenance costs of a machine. Therefore, managing this wear surface can deliver large $ savings. Utilizing Undercarriage Software requires integrating the inspections into the daily inspection routine across the job site. Points to consider when calculating the ROI:- Time and accuracy

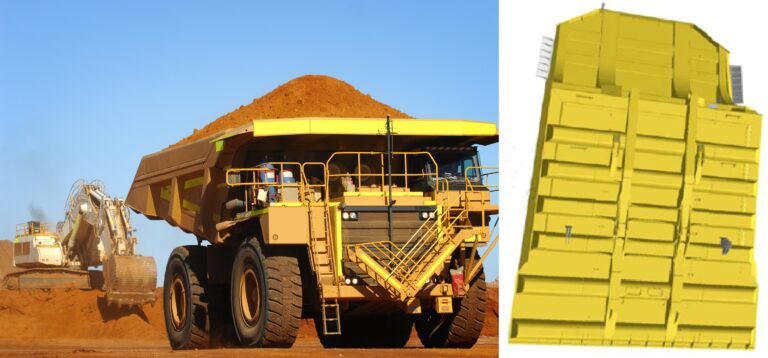

Digital Management of Dump Bodies made easy

Dump bodies on Off-Highway trucks are a typical component subject to wear rates based on the material being loaded. High wear areas may use sacrificial wear plates or GET for extra protection. Heavy loads can cause flexing of the body with resultant cracking. To track the life and performance of

Release Notes 7.8

Main Functions; Workshop Repair Estimates – Idler Rebuilds This additional functionality allows a user to complete an Idler Rebuild in the system, take measurements and photos. Interpret the information and the send this as a report to your customer. Reports can be fully customised as per your branding requirements, with

Undercarriage Measuring and Management capability internally at your mine-site is important to achieve 100% life on tracked machines.

Internal Undercarriage measuring and management capability can deliver large financial benefits

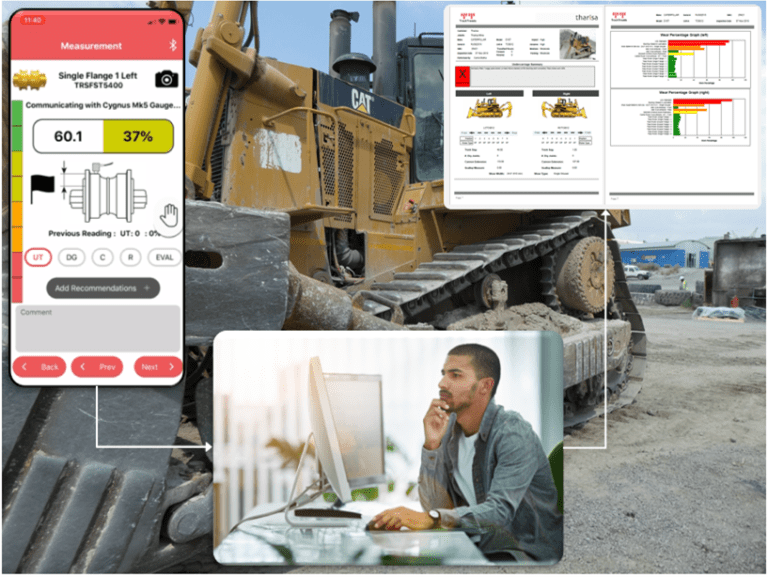

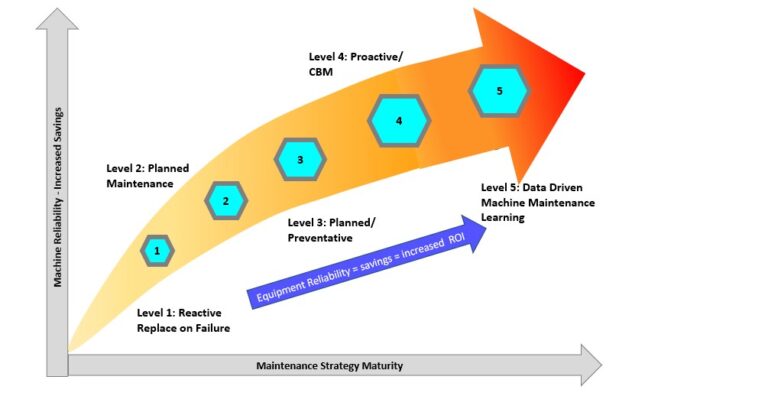

Digitized Field Inspection Tools to assist Reliability Planning

The task of Reliability Engineers and planners for the mine-site is to plan and schedule maintenance and repairs to the mobile equipment in order for the equipment to achieve as much uptime as possible for the least amount of cost. This is an extremely complex task requiring the planners to

Managing Undercarriage during times of throttled supply

The COVID Pandemic has led to a number of new market forces affecting business. Some among others is the slowing of supply chains including the availability of replacement undercarriage components. There are probably a few factors causing this: – Reduced manufacturing capacity at some period over the last 12 months,

Every Asset is as reliable as its weakest link

Every component on this machine needs to be regularly inspected to ensure that the machine remains reliable and productive. It is only as good as its weakest Link! Taking oil samples and performing PM’s is not enough to ensure Reliability Every component should be examined on a regular basis to

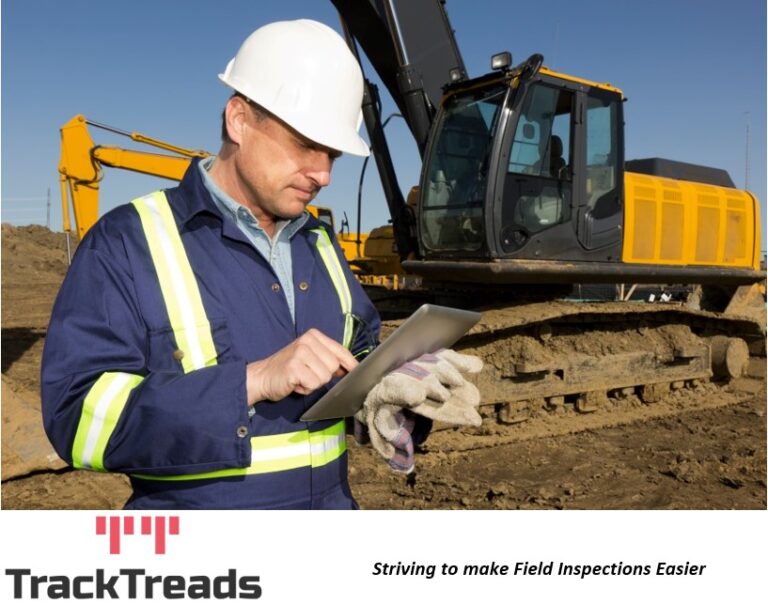

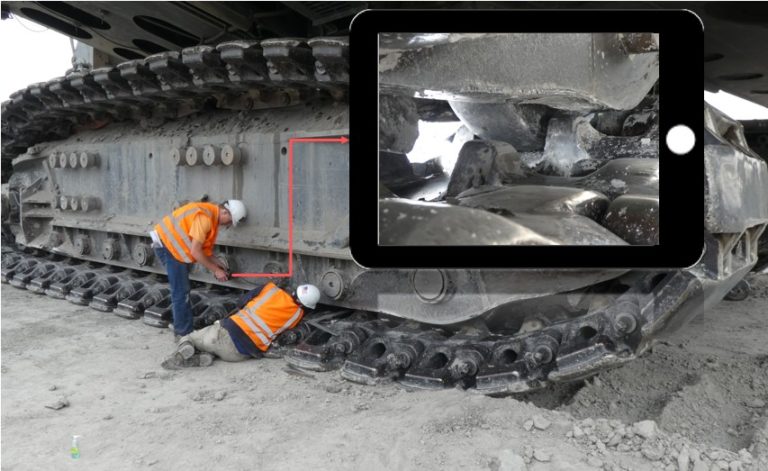

Technology helps make field inspections on Large Mining Machines safer and more efficient!

Moving Structural and Mechanical Inspections from paper-based forms and spreadsheets to a Digital version of the same form running on a phone or tablet, and allowing the same questions to be answered with measurements, images and comments provides many benefits and challenges to name a few Data Quality improves –

Component Rebuild Centre – Breathing New Life into your Tired Components

TrackTreads have released the Component Rebuild Centre as the latest module in their Undercarriage Management Tool Kit to support their customers increasing need to manage their equipment. The Component Rebuild Centre includes multiple inspections as the core of the management process commencing with: – Stage 1. Pre and Post Shipment

Release Notes 7.7

The digital field inspection functionality has been moved completely into the Undercarriage system thus doing away with extra security tokens which was slowing down users by forcing them to login multiple times when swapping applications. There is now just a single system All modules can now be accessed in the

Release Notes 7.6

UNDERCARRIAGE CHANGES Webapp Undercarriage – Rope Shovels Inspections now have the ability to add to a measurement point if it is an estimate or not, this brings out a blue dot next to the measurement point. Webapp Undercarriage Observation Point History Screen – we have now removed the green

Helping customers digitize their Field Inspections

Digitizing your Field Inspections delivers benefits in efficiencies, costs and control

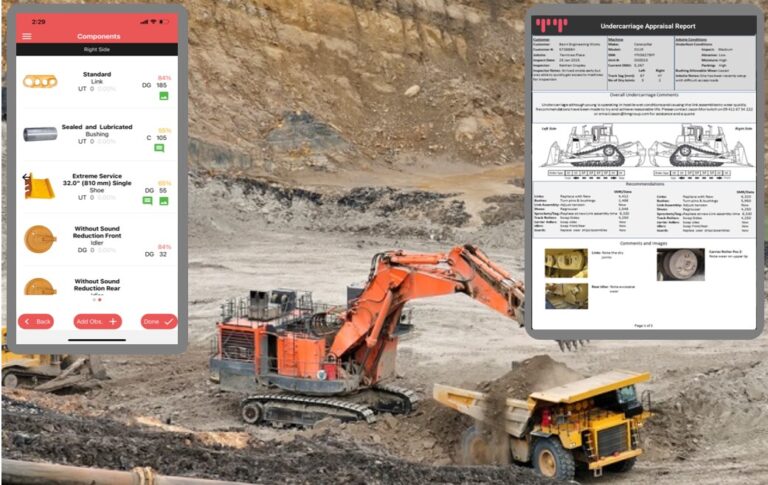

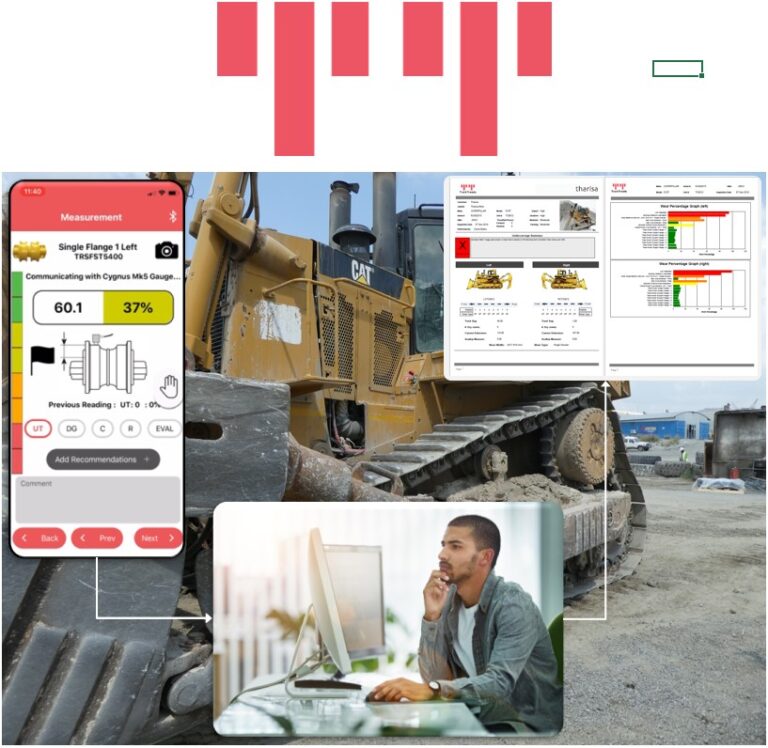

TrackTreads puts Heavy Earthmover Inspections at your Fingertips

The Mobile tool to make collection of Field Inspection observations and measurements easy and accessible

Next Step in Undercarriage Inspection Management

The TrackTreads Wear Management Software System is used for managing inspections on:- Undercarriage GET and Bucket’s including Dump Bodies Welded Structures Inspection data captured in the field with mobile phones – Measurements, images, comments and observations are captured using ordinary mobile phones, with functions to help the inspector understand the

Daily Inspections made simple with Mobile Phones

Daily field inspections become a rich source of data to enable early identification of component failures, provides a summary of equipment condition and ensures a safe working environment

Release Notes 7.5

Mobile app Undercarriage Inspection Loading Equipment to Inspect – Have enabled the ability to load multiple equipment to the mobile app in a single selection. This removes the bug experienced when loading multiple equipment in low strength WIFI signal and the system missing components. Webapp Digital Inspection Search – Increased speed when

TrackTreads releases new Microsoft Mobile Inspection Tools

TrackTreads are pleased to announce the release of its Inspection Management Tools for the Microsoft Environment. This gives inspectors the choice of using a Microsoft Platform in the field for capturing Inspection data. Advantages Include. No need to change your devices – Apple, Android and Microsoft supported Auto-Updates – removal

What ROI to expect from investing in Undercarriage Inspections on your jobsite

Investing in the implementation and use of Undercarriage Inspection Management Software needs to provide a return on investment. Undercarriage can make up more than 50% of the maintenance costs of a machine. Therefore managing undercarriage has the potential for large savings. How is the ROI measured:- Undercarriage Inspections guarantee better

Inspecting and Managing Undercarriage increases cashflow, profitability and improves Maintenance Scheduling

Undercarriage Inspections involve measuring each component using diferent tools and then using formula to calculate the % worn of the undercarriage components and the condition of the Undercarriage System. The percent worn of the component wear surface is then used to calculate the remaining life on each of the components.

Release Notes 7.4

This major release (our first of 2021) launches the Component Rebuild Centre. Other fixes and functions include; The ability to record the amount of links on each side of the Undercarriage Adding Images to an Undercarriage Inspection, from multiple sources Improving screen speed on Interpretation and Inspection screens Allowing for

Quoting and tracking the progress of large component rebuilds made easier with TrackTreads CRC software

TrackTreads Component Rebuild Centre software system focusses on tracking the detail of the rebuild at granular level to ensure a complete audit trail and accurate costing for any large component rebuild: – During the disassembly process, each observation points condition is analysed through inspection. This could be diminished material thickness

The dollars and Data Science behind Condition Based Maintenance Strategies

Condition–based maintenance (CBM) is a maintenance strategy that monitors the actual condition of the components to decide what maintenance needs to be done. CBM means maintenance intervention only when components are showing early signs of failure and the corrective actions performed, should put the component life back on track to achieve full life. The reduced maintenance interventions

Regular Structural Inspections are your Insurance Policy against costly Catastrophic Failures

Chassis, dump bodies and all complex welded structures are subjected to loading and torsional stresses during everyday use. Regular inspection and recording of cracks and condition enable a picture to be established of the structures general condition and when repair should be completed before a catastrophic failure occurs. Using the

Undercarriage Budgets set the Scene

Every Undercarriage has a budget or target life it is expected to live within a specific environment. This budget can be affected by Changes to the specific Environment Weather patterns for the year The Inspection regime identifying intervention maintenance required Budgets however perform a far more important role. They identify

Why identifying Critical Life Path Undercarriage Components is important

All Undercarriage Components wear at different rates and the aim of monitoring the undercarriage is to review the differences in the wear rates between the components and identify which components will limiting the life of the entire undercarriage system as a whole. This means identifying which components will wear out

Where does the advantage lie in Digitizing Undercarriage Inspections

The time taken to complete a full Undercarriage inspection manually on a dozer is on average about 20 to 25 minutes covering both sides. A field Rope Shovel inspection on the other hand can take between 2 and 4 hours depending on the number of inspection or observation points and

The most important Undercarriage Inspection is often missed

The most important Undercarriage Inspection is the End-of-Life inspection where the undercarriage components have reached the end of their useful life. This vitally important inspection is typically missed by most inspectors. So why is this inspection and the data so valuable. Undercarriage residual life is normally determined through inspection where

Field Inspection Images replace a thousand words

Images snapped in the field during an inspection to illustrate an issue identified creates a richer view of the problem and will often replace a thousand-word description of the problem. This saves enormous amounts of time which is money! Images speed up the inspection process because they save having to

A comprehensive Field Inspection Dataset has tremendous value to your business

Data that is collected over multiple inspections creates a dataset that can be extremely valuable to your business. So how can this be the case? Well there are a few reasons the dataset collected is specifically to your fleet of machines operated in your environment by your operators. This fact